slow-poke

Ultra Member

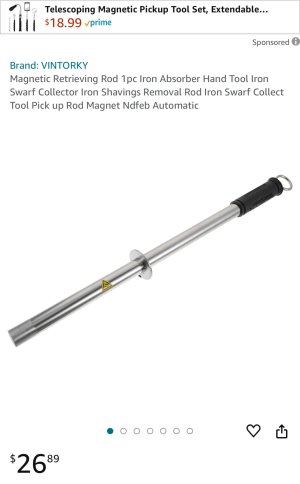

I was over at my friendly neighbors place the other day and he showed me a tool and stated "you really need to get one of these:"

Link-->

Really handy for reaching to the back of the lathe to retrieve swarf and also for picking up from the floor without bending over.

Anyone try one?

Being the kind of guy that never shies away from a new tool, I decided to make one. I'm going to use a stack of 18mm rare earth magnets, the ones with the little hole through the middle. I just made the end cap, used my new annular cutter arbor in the lathe to make the recess for the magnets, (thank's Susquatch).

Link-->

Really handy for reaching to the back of the lathe to retrieve swarf and also for picking up from the floor without bending over.

Anyone try one?

Being the kind of guy that never shies away from a new tool, I decided to make one. I'm going to use a stack of 18mm rare earth magnets, the ones with the little hole through the middle. I just made the end cap, used my new annular cutter arbor in the lathe to make the recess for the magnets, (thank's Susquatch).