Day ago my older lawnmower pusher started to show some age. I was already looking at possible replacement but my better half asked me very valid question - why do you have your expensive tools and nice workshop if you can't fix this simple thing, Here are photos of the broken hub for the wheel.

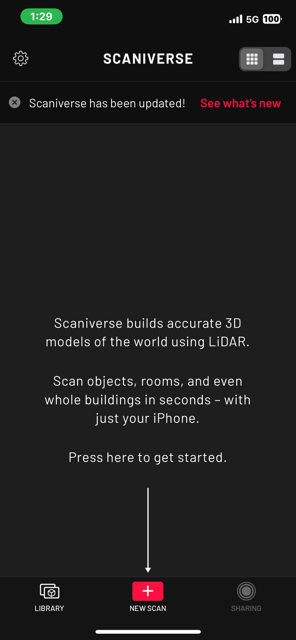

I made a 3D scan with my iPhone and it turned out to be quite good. Here is the scan.

After that replacement hub was designed and 3D printed with aluminum cast in mind.

I made a 3D scan with my iPhone and it turned out to be quite good. Here is the scan.

After that replacement hub was designed and 3D printed with aluminum cast in mind.