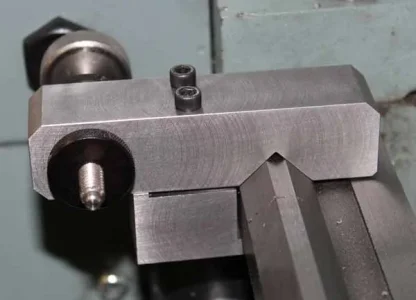

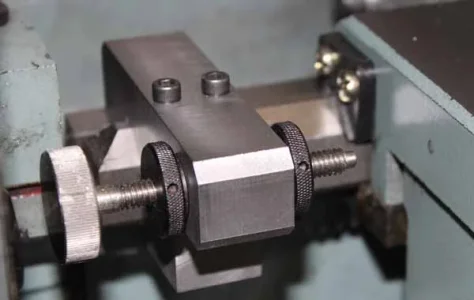

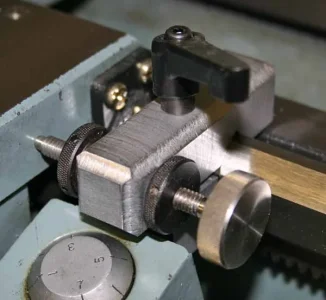

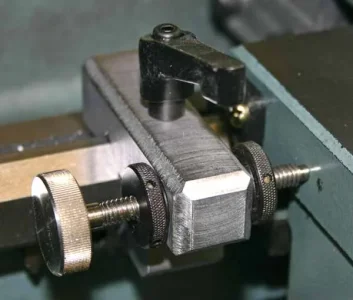

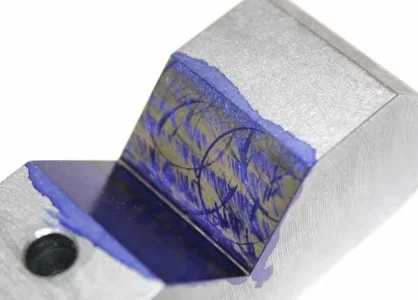

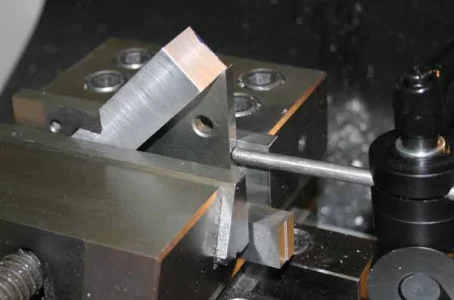

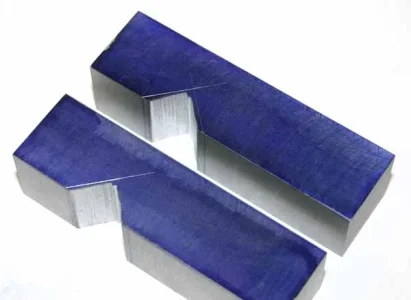

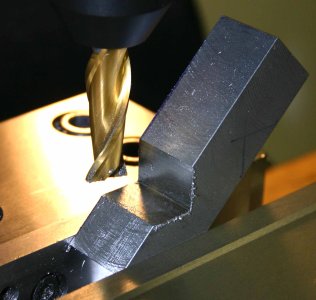

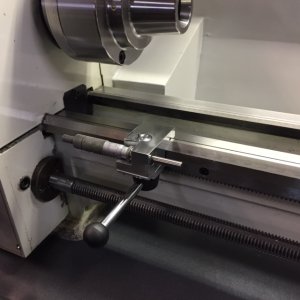

I actually made this accessory quite a while ago but snapped a pic for another purpose. Its useful when you want the carriage to come to a repeatable X position stop as you are removing stock in progressive passes. There are many variations out there, most are more functional than mine. Some have a rotating detent hub with different pin lengths so you can have a series of stops. Note, these are not meant to be contacted under power! You just gently contact the pin by hand, back out, reset in feed & repeat.

In hindsight I'd do things a bit different, so maybe give you some considerations for your own:

- I chose the threaded thumbscrew thinking I could machine the first pass to desired X dimension, then snug the screw to contact, tighten the nuts & then its nicely locked in position. That aspect is fine, but now I worry that if I ever fell asleep at the switch & contacted under traverse power, it would be a bad day: shear the lead screw pin, damage gears, maybe scrape the ways if it mangled the stop... So a maybe a better solution is a smooth pin that is clamped in position. Chances are better if it contacts that, it would push the pin & give you a split second of last minute save. But lets not think unhappy thoughts! Come off the power early with a safe margin & in-feed by hand.

- My 2 socket cap screws for clamping were just handy. But I would find one of those quick release, spring loaded adjustable clamp thingy's & save myself looking for yet another tool

- maybe make it adaptable to a cheapo plunger dial indicator stem. Its not really the same thing as a 'stop' but that's handy if you want to hit the same dimension within a thou.

In hindsight I'd do things a bit different, so maybe give you some considerations for your own:

- I chose the threaded thumbscrew thinking I could machine the first pass to desired X dimension, then snug the screw to contact, tighten the nuts & then its nicely locked in position. That aspect is fine, but now I worry that if I ever fell asleep at the switch & contacted under traverse power, it would be a bad day: shear the lead screw pin, damage gears, maybe scrape the ways if it mangled the stop... So a maybe a better solution is a smooth pin that is clamped in position. Chances are better if it contacts that, it would push the pin & give you a split second of last minute save. But lets not think unhappy thoughts! Come off the power early with a safe margin & in-feed by hand.

- My 2 socket cap screws for clamping were just handy. But I would find one of those quick release, spring loaded adjustable clamp thingy's & save myself looking for yet another tool

- maybe make it adaptable to a cheapo plunger dial indicator stem. Its not really the same thing as a 'stop' but that's handy if you want to hit the same dimension within a thou.