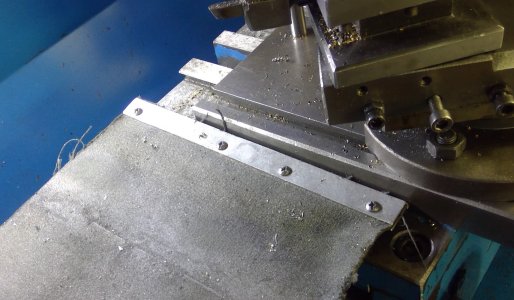

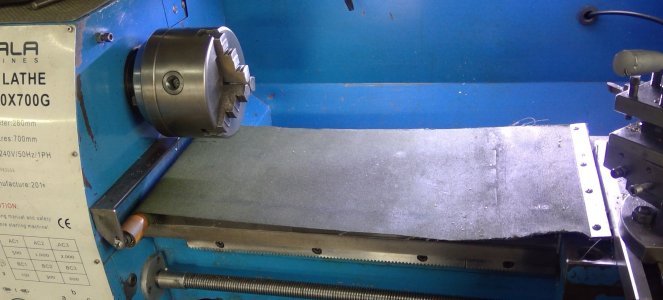

I made this bed protector a while back, waste of time really as I never remember to roll the thing out. But when I do it does work well.

The protetor sheet itself is heavy duty, oil impregnated green canvas. It's attached to a length 22mm round PVC pipe which rolls it up. I shrunk some larger PVC piping on the ends and fitted the ends with bearings, then made a carrier for it from angle iron which bolts to the headstock. There's a length of cord wrapped around the back end of the PVC pipe, which finds its way out the back of the stand via a couple of aluminium pulleys I turned up. Attached to the end of the cord is bit of 35mm steel which slide up and down inside a a length of PVC pipe fixed to the rear of the stand. The canvas is attached to the front of the carriage so when you wind the carriage back and forward the canvas rolls and unrolls around the PVC pipe, the weight of the 35mm steel keeping the canvas taught.

The protetor sheet itself is heavy duty, oil impregnated green canvas. It's attached to a length 22mm round PVC pipe which rolls it up. I shrunk some larger PVC piping on the ends and fitted the ends with bearings, then made a carrier for it from angle iron which bolts to the headstock. There's a length of cord wrapped around the back end of the PVC pipe, which finds its way out the back of the stand via a couple of aluminium pulleys I turned up. Attached to the end of the cord is bit of 35mm steel which slide up and down inside a a length of PVC pipe fixed to the rear of the stand. The canvas is attached to the front of the carriage so when you wind the carriage back and forward the canvas rolls and unrolls around the PVC pipe, the weight of the 35mm steel keeping the canvas taught.

Attachments

-

WIN_20230129_10_30_12_Pro.jpg306 KB · Views: 33

WIN_20230129_10_30_12_Pro.jpg306 KB · Views: 33 -

WIN_20230129_10_30_20_Pro.jpg295.1 KB · Views: 28

WIN_20230129_10_30_20_Pro.jpg295.1 KB · Views: 28 -

WIN_20230129_10_30_40_Pro.jpg327.1 KB · Views: 28

WIN_20230129_10_30_40_Pro.jpg327.1 KB · Views: 28 -

WIN_20230129_10_31_29_Pro.jpg367.9 KB · Views: 27

WIN_20230129_10_31_29_Pro.jpg367.9 KB · Views: 27 -

WIN_20230129_10_31_37_Pro.jpg256.1 KB · Views: 28

WIN_20230129_10_31_37_Pro.jpg256.1 KB · Views: 28 -

WIN_20230129_10_32_00_Pro.jpg278.9 KB · Views: 31

WIN_20230129_10_32_00_Pro.jpg278.9 KB · Views: 31