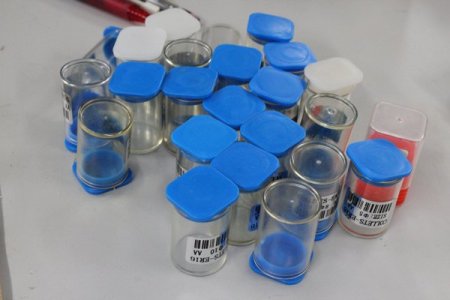

So I drew up an ER16 collet rack to fit a specific cardboard storage box size (after first printing a smaller 4-hole test block which I am happy with).

Its occupying some real estate on my A1 table. Total time ~7 hours. I'm sure the 'creature' printers are chuckling & calling me a WUS right now LOL

but this assumes default infill

Thus far I have found (PLA) prints around this thickness to be amazingly rigid for the purpose. What do you think, is this when people reduce infill to speed up time & reduce material? Or am I risking something else like potential lift or warp? Thus far my stuff has been smallish & actually impressed with what is coming off the printer.

Its occupying some real estate on my A1 table. Total time ~7 hours. I'm sure the 'creature' printers are chuckling & calling me a WUS right now LOL

but this assumes default infill

Thus far I have found (PLA) prints around this thickness to be amazingly rigid for the purpose. What do you think, is this when people reduce infill to speed up time & reduce material? Or am I risking something else like potential lift or warp? Thus far my stuff has been smallish & actually impressed with what is coming off the printer.