-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help wanted - transportation of a milling machine

- Thread starter smurray

- Start date

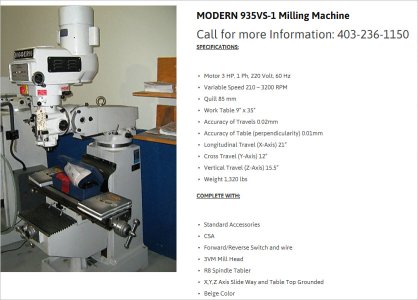

Pics, make/model ?

Probably more of a Clausing/Elgin. Seems a bit light for a Bridegport.

Uhaul has trailers with ramps that you could roll it on/off easy. Any steel bar 1/4 - 3/4 and it will roll well.

Had my lathe moved by a tow truck with a flat deck. Iirc it was $ 175 + tip for about an hour @ 20 km. You're a bit further but shouldn't be

horribad.

Probably more of a Clausing/Elgin. Seems a bit light for a Bridegport.

Uhaul has trailers with ramps that you could roll it on/off easy. Any steel bar 1/4 - 3/4 and it will roll well.

Had my lathe moved by a tow truck with a flat deck. Iirc it was $ 175 + tip for about an hour @ 20 km. You're a bit further but shouldn't be

horribad.

Dabbler

ersatz engineer

My heavy trailer is no more, alas. Rent a trailer and I'll help you move it. To prepare, we'd need to know the site details - it is far easier to unload than load, so what does the starting driveway look like - is is sloped, etc. I have rollers and pry bars, and you might ask Janger if he has something special to loan... If necessary, we can bring my portable (??) crane to load it with.

smurray

Member

Looks like it might be not needed as I couldn't move fast enough to get ahead of someone who has already put a deposit down on the mill. Disappointing but sometimes that's the name of the game. Sure would've been nice to upgrade from the round column mill that I have. It works just fine but it would've been nice to use gear changes, not having to reacquire my settings when I have to move the head up or down, etc. Thanks for the replies though. I appreciate you taking the time to help.

Tom Kitta

Ultra Member

If you have almost any pickup truck you simply should have driven over and placed it on the bed. 1000 lbs is not too heavy. My Tacoma easily handles 1000 lbs machines + in the bed but the gate cracked.

If they have nothing to load then renting a trailer is a better option as it is much lower and easier to load / unload. With a trailer and two people it should not take more than about 1h to load (if its right at the end of driveway/ next to garage door) and unload (next to door again). Pry bars and rollers help - through never needed rollers when unloading from a pickup - the angle is steep enough for it to slide nice on wood.

I moved multiple machines in that range so I now have a feel for it. This is FYI for the next mill you see on sale.

I am trying to figure out best way to move my own machines. About 3500 lbs each. Its a pain to unload them by hand. I cannot imagine how hard it is to load them by hand. Current idea is to use a pallet jack and a puller to pull them onto the trailer and then roll them off.

If they have nothing to load then renting a trailer is a better option as it is much lower and easier to load / unload. With a trailer and two people it should not take more than about 1h to load (if its right at the end of driveway/ next to garage door) and unload (next to door again). Pry bars and rollers help - through never needed rollers when unloading from a pickup - the angle is steep enough for it to slide nice on wood.

I moved multiple machines in that range so I now have a feel for it. This is FYI for the next mill you see on sale.

I am trying to figure out best way to move my own machines. About 3500 lbs each. Its a pain to unload them by hand. I cannot imagine how hard it is to load them by hand. Current idea is to use a pallet jack and a puller to pull them onto the trailer and then roll them off.

Dabbler

ersatz engineer

We easily moved my 3800 lb mill into my garage from the truck - there were two of us: me and a 73 year old friend. We did use a pallet jack to get it to the plywood ramp, and rollers to move it into the garage. (the truck had a power tailgate). I moved my 2200lb mill from my trailer by myself. No excitement, just took an hour or so.

Note it is a uphill slope from the unloading place to the garage door, and a side hill as well, this just requires a little thought and planning. Tom I'm sure you know what I mean.

I find it is very easy to run the machine down steel rails from the trailer to the plywood. Just enough friction, but not too much.

Note it is a uphill slope from the unloading place to the garage door, and a side hill as well, this just requires a little thought and planning. Tom I'm sure you know what I mean.

I find it is very easy to run the machine down steel rails from the trailer to the plywood. Just enough friction, but not too much.

A crane truck makes things much easier. They’re not that expensive. I’ve spent about $250 twice and thought it was money well spent. I didn’t spend it once and it was nearly a disaster. Some Very fast thinking and reaction by another forum member kept my mill from tipping over and probably busting when we were trying to get it down a slope into the alley where we could use a engine hoist. I’m glad nobody got hurt.

Dabbler makes it look easy. It’s not too hard until it is hard and then I think it’s awful. Be careful!

Dabbler makes it look easy. It’s not too hard until it is hard and then I think it’s awful. Be careful!

Attachments

-

E7F72224-3D6B-4513-AF8B-78682CAC8F26.jpeg109.1 KB · Views: 29

E7F72224-3D6B-4513-AF8B-78682CAC8F26.jpeg109.1 KB · Views: 29 -

700C8FEF-8200-493F-8FD5-E01FD0FB7D8B.jpeg138.4 KB · Views: 31

700C8FEF-8200-493F-8FD5-E01FD0FB7D8B.jpeg138.4 KB · Views: 31 -

94DA54FC-4BCC-4DAB-B5AB-60D60424896F.jpeg154.5 KB · Views: 31

94DA54FC-4BCC-4DAB-B5AB-60D60424896F.jpeg154.5 KB · Views: 31 -

A6654B14-03DD-4643-B922-30241EA2832C.jpeg150.3 KB · Views: 32

A6654B14-03DD-4643-B922-30241EA2832C.jpeg150.3 KB · Views: 32 -

02B07E38-ACE9-4324-B1EE-719CFB734118.jpeg129.6 KB · Views: 32

02B07E38-ACE9-4324-B1EE-719CFB734118.jpeg129.6 KB · Views: 32

Last edited:

You could try these guys too. Logical choice trucking.

None of these guys are professional machine tool riggers. They are truck drivers. Moving a machine is a little unusual for them. Plan how you want it lifted and use the lift points/holes if there are any. Lifting through the holes in the castings is probably a bad idea although I’ve heard it argued either way. Bending or breaking is the usual argument against doing it that way.

None of these guys are professional machine tool riggers. They are truck drivers. Moving a machine is a little unusual for them. Plan how you want it lifted and use the lift points/holes if there are any. Lifting through the holes in the castings is probably a bad idea although I’ve heard it argued either way. Bending or breaking is the usual argument against doing it that way.

Attachments

Dabbler

ersatz engineer

When the machine has no obvious lifting points, just look at the strongest places and ensure that the machine is supported well, without undue stress on it. Two things to keep in mind - delicate things such as the lead screw on a lathe (PeterT has things to say about this) (not his fault), and ensure there are no sharp edges that will damage the lifting strap(s). BillP cut his on the dovetails on his mill - it only fell a few inches, fortunately.

Hiring a professional machine tool rigger can cost as much as a used machine or more(!), but if you are careful and go slow, it can be safe.

Hiring a professional machine tool rigger can cost as much as a used machine or more(!), but if you are careful and go slow, it can be safe.

I have a question for you guys (having dangerous$ upgrade thought$). I have seen pics of guys using low profile wheeled forklift thingy's. Maybe they are called pallet jacks? They move machines along the concrete floor into home position or even around to different parts of the shop & seems like mitigates the need for an overhead lifting hoist assembly? Can low profile floor jacks be rented? Can the forks set closer or angled inward to get inside a casting base with feet? Example mill is 1300 pounds, is that doable with floor jacks?

Here are some bases others have built for mini Bridgeport size machines. I think partially to elevate the machine, facilitate leveling feet & get underneath for moving around when there is limited ceiling headroom (all relevant in my case).

Here are some bases others have built for mini Bridgeport size machines. I think partially to elevate the machine, facilitate leveling feet & get underneath for moving around when there is limited ceiling headroom (all relevant in my case).

Attachments

Dabbler

ersatz engineer

OK so here goes... the pallet jacks you rent are usually the wide ones, but are quite inexpensive if bought used, and you wait for a deal. the really narrow ones (Jimbo has one, are rarer, much more expensive, and not usually rentable). However for moving a mill around a concrete floor, I much prefer to do it with 1" pipes (or 1.25" solid rounds), because then I am using a pry bar, and I get there nice and slowly with no drama. (Remember Janger's post above?) - on downhill slopes i use a pry bar and slide it down steel rails, I mostly use 1" angle iron, corner up.

My garage has 8' headroom (Or is it 8'2"?) and I have plenty of room for a full sized 9X49 BP clone. In fact, mine was on two pallets (making it 9" higher, and I had to lift it UP to get the pallets out...) I think for any mini-mill or even full sized mill, you can get it under the 7'8" of a standard stud height wall with single and double sill plates.

It is important to have the mill firmly touching the floor, and the levelling feet help to remove vibration and make even contact with the concrete.

Some guys put their mill on wood structures, but I've never seen a professional shop do this.

My garage has 8' headroom (Or is it 8'2"?) and I have plenty of room for a full sized 9X49 BP clone. In fact, mine was on two pallets (making it 9" higher, and I had to lift it UP to get the pallets out...) I think for any mini-mill or even full sized mill, you can get it under the 7'8" of a standard stud height wall with single and double sill plates.

It is important to have the mill firmly touching the floor, and the levelling feet help to remove vibration and make even contact with the concrete.

Some guys put their mill on wood structures, but I've never seen a professional shop do this.

Some guys put their mill on wood structures, but I've never seen a professional shop do this.

Agree. But for us guys with LSS (Limited Shop Space) who often need to move stuff, I like the idea. If I had a big mill I'd spend a few extra bucks and buy a composite pallet. No rot, dead level, and they look better too.

A crane truck makes things much easier. They’re not that expensive.

While I'd like to learn how to rig stuff better myself, and I am building a gantry crane, I've hired crane trucks before, and had Modern bring theirs once. Totally worth it to me as well.