Funny... Ask and the universe provides. I did notice that Keith Rucker posted the very

same procedure on his youtube channel yesterday. I'm a long ways away from attempting something like this myself...

That;s another great use for swivel table, its the same set up to cut say a flute in a drill blank; helical milling.

just for posterity....that is a quite different process from what I was suggesting - hobbing. The method he shows approximates the gear tooth (which may or may not be adequate) whereas hobbing is true generation. With hobbing, The table is only every swung to, and must be at, the hob's helix angle, a fairly small but small but crucial angle (if you want a helical gear you angle the work axis relative to the table axis). The the spindle rpm's and work rotation have to be synched. That is a such gnarly complex bit of gearing you didn't used to see many trying to hob on a mill, but electronics changed and a few brave souls have done wonders with it....an encoder on the spindle and stepper on the work and a bit of calculation does the trick

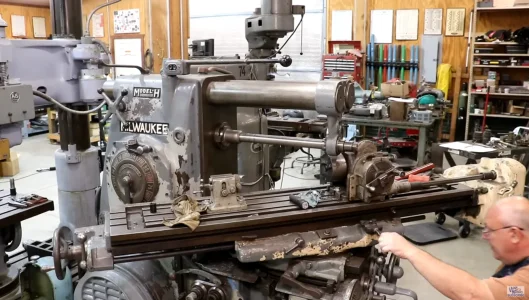

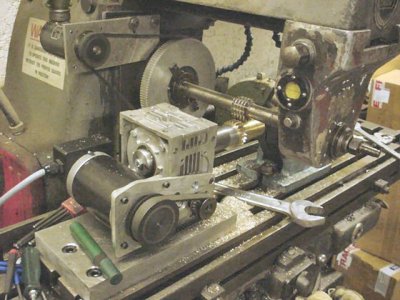

The late John Stevenson did a lot of work in this area and published a bunch material. Here's what a hob looks like. table is at a slight angle - that pattern on the hob is a helix, and the table angle is the helix angle...like a rack profile wrapped around a cylinder..

btw, you can do the same with vertical mill (tilt the head to the helix angle), its just not as solid.

This is all John's work and photos, not mine

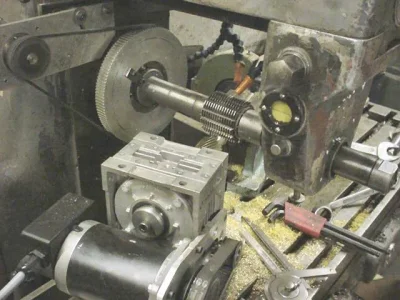

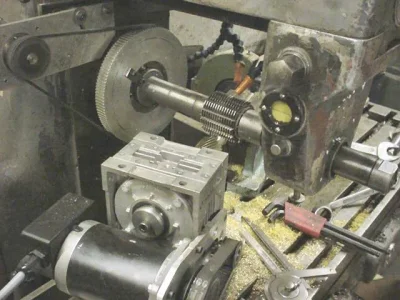

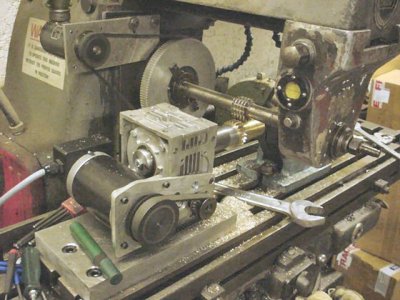

work and cutter rotation is coordinated - cut is just staring here

shot showing how it works

for a helical gear, angle the work relative to the table motion (table is already swung over by the helix angle of the hob)