darrin1200

Darrin

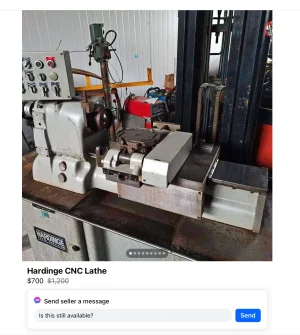

My brother-in-law spotted this, he was attracted by the price. It says it’s a cnc project, but it also looks like a specialty lathe.

Its not a project I’d take on, but for $700, I thought someone would be interested.

www.facebook.com

www.facebook.com

Its not a project I’d take on, but for $700, I thought someone would be interested.

Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

Last edited by a moderator: