-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gadget - multi purpose

- Thread starter Janger

- Start date

What are you making Janger?

Did you really have to ask that? Now he is gunna tell us for Pete Sake!

DPittman

Ultra Member

Oh sorry it was probably obvious if I could keep track of other peoples projects. Most days I'm doing good to remember my own!Did you really have to ask that? Now he is gunna tell us for Pete Sake!

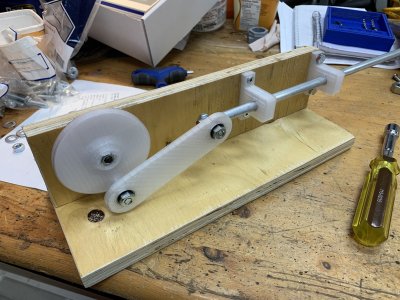

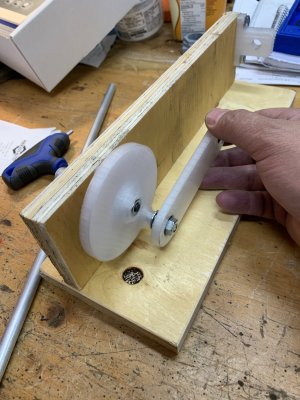

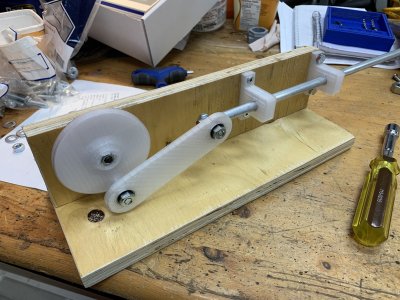

It’s a rattle can shaker! I don’t own one of those cut off saws so I made this - drill powered. In testing I broke the wheel so now I’m printing it again with a more robust polycarbonate plastic and more perimeters and interior fill.

Attachments

To control a potentiometer? How and why?That is essentially what I made to change the linear movement of a sewing machine treadle/pedal into a rotary motion to co trol a potentiometer. What are you making Janger?

DPittman

Ultra Member

Post in thread 'First gear cutting' https://canadianhobbymetalworkers.com/threads/first-gear-cutting.6217/post-105323To control a potentiometer? How and why?

Sorry Janger, I cannot imagine the day that I need to resort to an electric drill to shake a spray can of paint!It’s a rattle can shaker! I don’t own one of those cut off saws so I made this - drill powered. In testing I broke the wheel so now I’m printing it again with a more robust polycarbonate plastic and more perimeters and interior fill.

And, I can actually see, how the mechanism would work to change a linear motion, in to a Rotary one, per the example above.

I do know the old saw about when all you have for tools is a hammer, every problem looks like a nail, but... Nah. Still thinking this is going backwards!

Did you really have to ask that? Now he is gunna tell us for Pete Sake!

Yeah, that's the ticket, its a paint can shaker!

Sorry Janger, I cannot imagine the day that I need to resort to an electric drill to shake a spray can of paint!

Yeah, that's the ticket, its a paint can shaker!

Yup, somebody just had to ask.....

Pretty sure @Janger's next project is to build that gizmo into his mr gadget hat...... I'm gunna hate the guy who asks him what the trap door on the hat is for ......

This is one of the fundamental engineering mechanisms. Rotary to linear or linear to rotary. I wanted to build one just to design and make all the parts.

Linear to rotary - this type of mechanism of course in (nearly) every locomotive and car engine today - it's just under the covers. Here you can see it.

Rotary to linear

Linear to rotary - this type of mechanism of course in (nearly) every locomotive and car engine today - it's just under the covers. Here you can see it.

Rotary to linear

Very nice animation of shaper mechanism. It clearly reveals just how the arm retracts faster than the work stroke. The pivot point moves changing the speed of the lever. it's very clever I think. I just learned this today. Anybody with a shaper take some photos with the covers off? (@kevin.decelles I think you are the reigning shaper champ?)

The pivot point moves changing the speed of the lever. it's very clever I think.

I did some numbers and calcs for someone on here a while back. I'll see if I can find them.

Credit roll... since I'm watching the Oscars while I type this:

First credit goes to Autodesk and the Fusion 360 CAD/CAM product. Using it I designed all these parts. Quite a step up from ClarisCAD!

Second credit goes to the open source programming community who wrote Slic3r which is the core of the Prusa Slicer. WIthout a slicer a 3d printer is just a glue gun.

And last credit goes to Prusa who make the Prusa EDIT-> MK3S+

It's a nice printer and I've printed many many parts with it. Thanks @Jwest7788 for encouraging me to just spend the money on a good printer.

First credit goes to Autodesk and the Fusion 360 CAD/CAM product. Using it I designed all these parts. Quite a step up from ClarisCAD!

Second credit goes to the open source programming community who wrote Slic3r which is the core of the Prusa Slicer. WIthout a slicer a 3d printer is just a glue gun.

And last credit goes to Prusa who make the Prusa EDIT-> MK3S+

It's a nice printer and I've printed many many parts with it. Thanks @Jwest7788 for encouraging me to just spend the money on a good printer.

Last edited:

Quick return mechanism - Wikipedia

more animations and a good article

TorontoBuilder

Ultra Member

That slotting machine is in my to build list@Janger I know you said die filer but there are are quite a few useful slotting attachment ideas that use a similar connecting rod / pseudo-shaper principle ranging from hand powered to bigger wattage motor driven. I will have to delve into this at some point in my future.

View attachment 32060

And last credit goes to Prusa who make the Prusa 3MKS+

I tried looking up that printer but got something slightly different. Did you mean Prusa MK3S+ ???