I might be scraping some surfaces soon, so I figured I should prepare.

Made this out of an old dull useless file.

The actual scraping point is from an HSS planer blade.

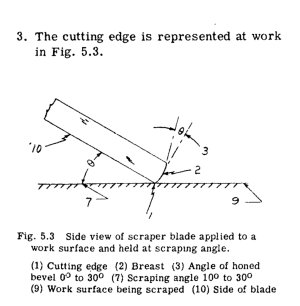

Overall length is 16". I think I ground the blade a little too sharp, so it wants to carve instead of scrape.

Now to practice....a lot!

Made this out of an old dull useless file.

The actual scraping point is from an HSS planer blade.

Overall length is 16". I think I ground the blade a little too sharp, so it wants to carve instead of scrape.

Now to practice....a lot!