lucsimoneau

Well-Known Member

Hi all,

Had a few hours to play with my CX706 lathe since buying it this summer, never got around to installing the 4-Jaw chuck or the mounting plate.

Kind of a special deal compared to standard lathe spindle attachments that I'm use to so I thought I would share what I've learned.

The spindle nose has a MT4 internal taper and the following configuration:

You can attach the spindle using a special "locking ring" wish is held in place by a few M6 cap screws threading into oblong nuts on the headstock side:

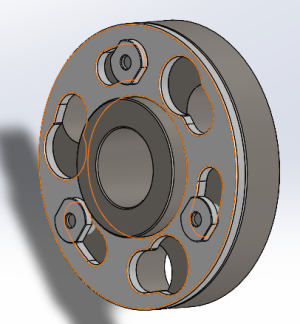

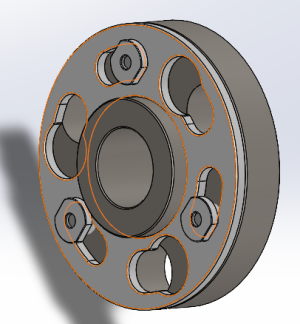

The backing plate is attached to the chuck (different plate for the 3 jaw or 4 jaw chuck) using some spindle "studs" and a few M8 hex bolts as shown:

So when everything is installed, the spindle/chuck assembly looks like this (3 Jaw / 4 Jaw):

When installing the mounting plate, no backing plate is needed:

I was trying to find the actual part numbers in the CX706 manual but not much info is available concerning the chucks and locking ring.

Attached is the PDF file of the actual chucks which are SANOU K11-125 (3 jaw) and SANOU K72-125.

Merry Christmas!

Had a few hours to play with my CX706 lathe since buying it this summer, never got around to installing the 4-Jaw chuck or the mounting plate.

Kind of a special deal compared to standard lathe spindle attachments that I'm use to so I thought I would share what I've learned.

The spindle nose has a MT4 internal taper and the following configuration:

You can attach the spindle using a special "locking ring" wish is held in place by a few M6 cap screws threading into oblong nuts on the headstock side:

The backing plate is attached to the chuck (different plate for the 3 jaw or 4 jaw chuck) using some spindle "studs" and a few M8 hex bolts as shown:

So when everything is installed, the spindle/chuck assembly looks like this (3 Jaw / 4 Jaw):

When installing the mounting plate, no backing plate is needed:

I was trying to find the actual part numbers in the CX706 manual but not much info is available concerning the chucks and locking ring.

Attached is the PDF file of the actual chucks which are SANOU K11-125 (3 jaw) and SANOU K72-125.

Merry Christmas!