-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

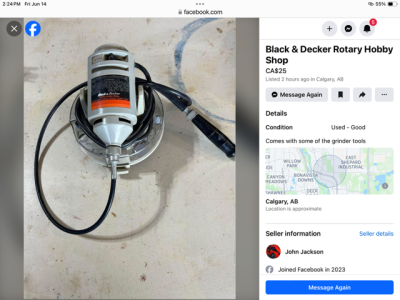

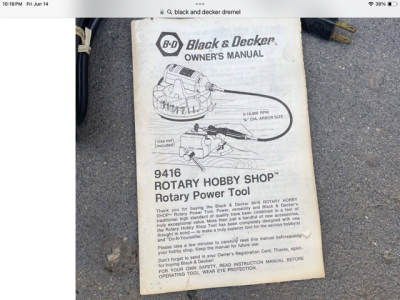

Cable grinder dremel

- Thread starter Tom O

- Start date

Cant go wrong for what you paid. Foredoms are probably $450 these days. There are Chinese knockoffs for about half. B&D made some decent tools back in the day but they also went through various stages of outsourcing quality. The only thing is you may be on your own with the flex shaft. My friend had one (not a B&D) & none of the Foredom or Dremel flex shafts would fit the thread/shaft geometry on the motor end.

I don't have his style myself but was looking hard for a while. Jewelers say a Foredom will last a lifetime of daily use. I ended up buying a very light weight variable speed tool. The (electrical) cord to the variable speed box is so light you cant even feel its there. That's the other thing I heard about some of the, particularly clone, flex shafts is they can be a bit stiff & influence the way you work with the tool. But that might be coming from people that do real tiny stuff.

I don't have his style myself but was looking hard for a while. Jewelers say a Foredom will last a lifetime of daily use. I ended up buying a very light weight variable speed tool. The (electrical) cord to the variable speed box is so light you cant even feel its there. That's the other thing I heard about some of the, particularly clone, flex shafts is they can be a bit stiff & influence the way you work with the tool. But that might be coming from people that do real tiny stuff.

I’ll see how it turns out as far as the flexibility goes I can see that but I believe it’s what you get use to using and like you said how delicate the project is. The end of the flex shaft looks like a speedometer cable so I don’t think it will be a problem if it ever breaks I’m not sure about the liner though.

What I was reading on (primarily jewelry & small stuff) forums is that not all flex shafts are created equal. Some guys who sprang for the Foredom knockoffs were perfectly happy with the motor side of it, but the power cable was significantly stiffer which of course translates to your hand as its trying to make subtle strokes & angles & positioning. Some clones were indistinguishable but only to a certain RPM & then developed some funky harmonics (vibration) which is a bad thing. usually high speed means small burr & finesse operation, the last place you want unwanted buzz. For say wood carving, probably would never notice a difderence? I kind of lost the scent but some clones were able to adapt actual Foredom replacement kits & others less successful, either because they failed to clone it properly or tweaked it on their own without really knowing what they were doing.

Foredom makes a whole bunch of different kinds of handpieces, collets, chucks etc. But I've also read Foredoms really should be hung up on a tree vs flat on a table (even though they sell a pivoting lazy susan type base). So I dunno, as mentioned I dont have one myself, I was just lurking. I got to run my friends briefly at his shop which WAS hung on a tree & it seemed quite smooth but I was conscious of the flex shaft. I'm a longtime handheld Dremel guy so I'm sure just takes getting used to. Holding an entire 'motor' (Dremel) in your hand is not fun over extended periods either.

The flex shaft lubrication & maintenance side is apparently quite important to do regularly. There are some YouTube vids (amounts to basically cleaning &re-greasing when it comes right down to it). This might help visualize the different kinds of ends they use & I think even taht has changed over the years.

Foredom makes a whole bunch of different kinds of handpieces, collets, chucks etc. But I've also read Foredoms really should be hung up on a tree vs flat on a table (even though they sell a pivoting lazy susan type base). So I dunno, as mentioned I dont have one myself, I was just lurking. I got to run my friends briefly at his shop which WAS hung on a tree & it seemed quite smooth but I was conscious of the flex shaft. I'm a longtime handheld Dremel guy so I'm sure just takes getting used to. Holding an entire 'motor' (Dremel) in your hand is not fun over extended periods either.

The flex shaft lubrication & maintenance side is apparently quite important to do regularly. There are some YouTube vids (amounts to basically cleaning &re-greasing when it comes right down to it). This might help visualize the different kinds of ends they use & I think even taht has changed over the years.

Shafting | Foredom Electric Company

Most current and discontinued motors use a Standard S-93 Key Tip Inner Shaft and S-77 Outer Sheath that work with Key Tip Handpieces. Motors that come equipped with Square Drive shafts and sheaths (shown in video clip above) have the letter ‘H’ (Series SRH, TXH, LXH). Square Drive shafting is...

www.foredom.net

I'm a longtime handheld Dremel guy so I'm sure just takes getting used to. Holding an entire 'motor' (Dremel) in your hand is not fun over extended periods either.

You almost make me cry Peter.

I have owned two rechargeable Dremel Stylus units and LOVED them. You could work for hours with one and never get tired. They almost felt like you were using a paint brush or large fountain pen. I've done some very amazing work with them.

I REALLY miss mine. The batteries failed and I couldn't get replacements. But to be honest, the bearings prolly weren't far behind.

I have NO IDEA why they were discontinued.

Out with the old, in with the new! LOL. After some deliberation I passed on the Foredom & bought this one. Its a joy to use, so light in your hand & the motor is so smooth. I still keep my Dremel's busy until they die for more routine work (well, my Milwaukee cordless is the go-to tool truth be known). These smaller units go to 45Krpm but a downside is they are typically limited to 1 or 2 close tolerance collet sizes, nominally 3/32" & 1/8" (or their metric equivalent if you buy an offshore unit).

Last edited:

my Milwaukee cordless is the go-to tool truth be known

I have one too, but I don't love it. Lots of oomph but It's too heavy and too awkward.

Nobody has mentioned my biggest bitch about the pencil design. When they grab, you don't have enough grip to resist the bit and mistakes happen.

The Stylus has a pistol grip that you can hold very firmly and comfortably. None of the other designs have that.

Yup. Grab is largely a function of tooth (or grit) height & RPM & the material of course. Gummier or softer being more problematic. When rpm is limited we tend to infeed more & unlike a mill or lathe, our hand is not backstopped by anything rigid. Once loaded or planted or otherwise stalled, the cutting tool has nowhere else to go so kicks out of its cut. That's partly why dental rotary tools & drills spin at 100-400 K RPM.

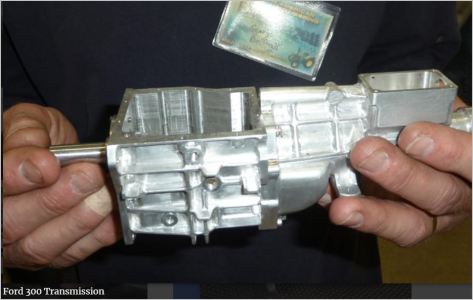

This model engineer does a lot of manual machine (no-CNC) carving & blending with rotary tool in aluminum (after roughing of course). Once done you would never know the weren't precision cast.

This model engineer does a lot of manual machine (no-CNC) carving & blending with rotary tool in aluminum (after roughing of course). Once done you would never know the weren't precision cast.

Re Milwaukee & other cordless for that matter, its partly an overall weight thing & partly center of gravity thing. Both brought on my the battery in the rear end. More power means bigger motor & with that comes bigger capacity and/or voltage, means more weight. Lithium based cells sure help a lot, but is always a compromise. Next step up is basically die grinders unless you go pneumatic.I have one too, but I don't love it. Lots of oomph but It's too heavy and too awkward.