Log into Facebook

Log into Facebook to start sharing and connecting with your friends, family, and people you know.

www.facebook.com

www.facebook.com

www.facebook.com

www.facebook.com

Yeah. It could easily D1-3 or D1-4. I even have a D1-6 that has only 3 pins!You’d think they’d identify what camlock size it was?

.......or the diameter. If 8", it would have been a great addition to the shop. It sold pretty quick I think. Saved myself $100 by not being on Facebook. The wife asked for me, and it was gone by around 6-7:00.I was kind of annoyed, the seller’s profile photo is for ‘Wright Machining Service’. You’d think they’d identify what camlock size it was?

Hmm, tempted to pick one up. Small for my lathe, but sometimes that's handy, and at that price...If you're interested Dan may still have a few 5" chucks on a 1.5" x 8tpi backing plate left around. You would just need a backing plate to fit your machine but at $190 CDN you won't find a Bison any cheaper.

3 and 4 jaw chucks for bench lathes

6" Atlas original 4 jaw lathe chucks and Bison 5" 3 jaw chucks with 1 1/2 x 8 integral mountswww.hhrobertsmachinery.com

These are NOS from the 1980s when they bought a pallet load of them so they need a good cleaning. Quite a few of us on the forum have bought them.

I am among the counted. Happy w/ the chucks (got a 3- & 4-jaw).Quite a few of us on the forum have bought them.

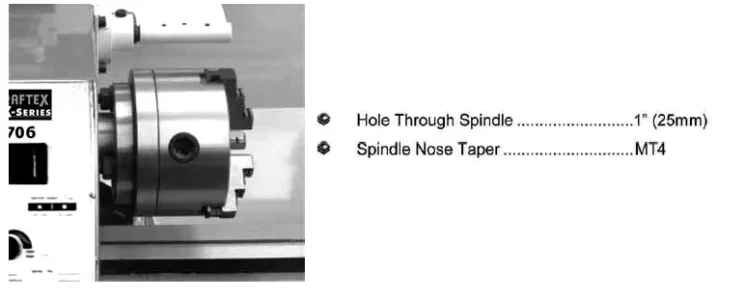

My lathe has a MT4 taper for the spindle. So I guess I would need something between to use it.I forgot to talk about compatibility. Bison chucks can be depended on to adhere well within the tolerances of the D1-x standard. If your lathe is standard adhering, the chuck would have fit it.

My lathe has a MT4 taper for the spindle.

That seems odd. Did you mean that your spindle has an MT4 taper INSIDE IT? Surely that isn't the primary drive system. Doesn't it also have a threaded spindle nose or a D1-x or or or? If so, I'd use that, not the morse taper.

The normal method is to get a back plate to fit your spindle and fit the backplate to the chuck.

Maybe I don't understand your question.

canadianhobbymetalworkers.com

canadianhobbymetalworkers.com