I bought these a while back & finally got around to trying them out. I pulled 5 of them just randomly matched to very new metric carbide end mills. They all all measured within 0.0005" TIR (without really knowing how the EM's themselves compare). Good enough for the purposes I had in mind.

I did some milling with them today, no problem. But it actually reminded me of why I prefer my ER holder. With R8 you have to kind of hold the EM into the collet by the Ouchy end & simultaneously tighten the drawbar with the other hand, which is a bit of stretch for me (Bridgeport clone). In the past I've dropped EM's out of the collet if its not quite tight enough initially. All it takes is a low altitude drop to chip the edge & bye-bye EM. Maybe there is a better way to do this, I dunno. With an ER holder you put EM in collet & snug the nut, everything is there right in front of you.

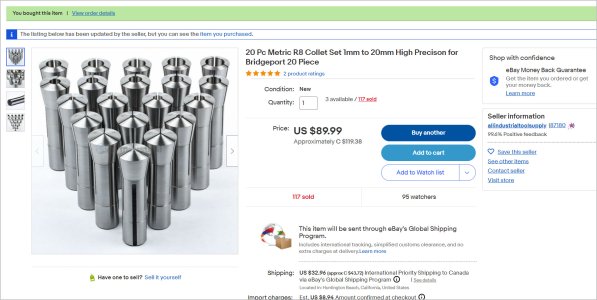

This is the Ebay store.

www.ebay.ca

www.ebay.ca

I did some milling with them today, no problem. But it actually reminded me of why I prefer my ER holder. With R8 you have to kind of hold the EM into the collet by the Ouchy end & simultaneously tighten the drawbar with the other hand, which is a bit of stretch for me (Bridgeport clone). In the past I've dropped EM's out of the collet if its not quite tight enough initially. All it takes is a low altitude drop to chip the edge & bye-bye EM. Maybe there is a better way to do this, I dunno. With an ER holder you put EM in collet & snug the nut, everything is there right in front of you.

This is the Ebay store.