Jswain

Joe

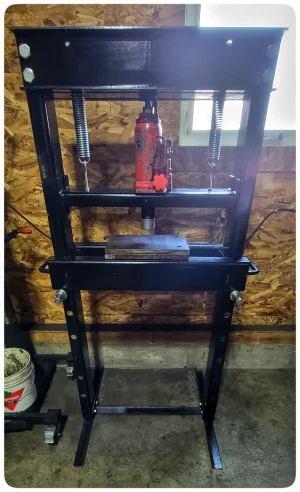

Found a reason to start another project.

Picked this guy up for $75. Didn't come with any plates but I have 4 pieces of 3/4" that'll work. I believe it's 20t, unsure about the bottle jack but it works & holds pressure. Top beam has a very slight curve to it, may weld in a piece of 3/4" plate where the bottle jack pushes but we'll see.

Might upgrade to an air - hydraulic jack, will definitely build a new press brake for it(maybe swag finger style). And have to flip the right leg around. I have my 12t on wheels but I may leave this one without.

I really like that the press pin is threaded, gives me some things to machine.

Picked this guy up for $75. Didn't come with any plates but I have 4 pieces of 3/4" that'll work. I believe it's 20t, unsure about the bottle jack but it works & holds pressure. Top beam has a very slight curve to it, may weld in a piece of 3/4" plate where the bottle jack pushes but we'll see.

Might upgrade to an air - hydraulic jack, will definitely build a new press brake for it(maybe swag finger style). And have to flip the right leg around. I have my 12t on wheels but I may leave this one without.

I really like that the press pin is threaded, gives me some things to machine.