But I was more apprehensive of buggering of the gib.

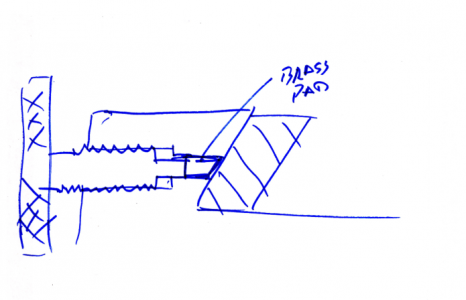

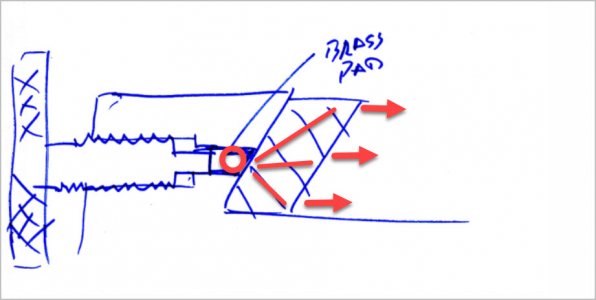

So I tried this first & it worked. To recap = the brass angle mates the gib angle & presses laterally. Yes its bending the gib, but I would guess very little just based on the existing sliding fit.

Other than marring of the surface with a turning screw end, I wouldn't worry about damaging the gib. As you say, it's already a close fit and can't really bend much at all. The main locking force isn't the wedge or the screw anyway. It's the fact that the dovetail on the opposite side locks across its whole length that locks everything up solid.

When I install my DRO (hopefully this summer) I'll take a really close look at making a wedge arrangement for mine if only to reduce the marring that will inevitably take place with a lock screw that is turning against the gib.