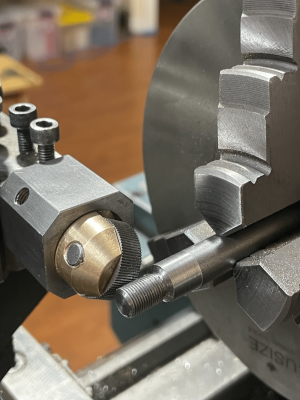

I was quite shocked at the cost of a cut knurl tool from a commercial supplier - $400 - $700 and even more for a fancy one. So I took a day and made this lovely little thing. It does the job perfectly!

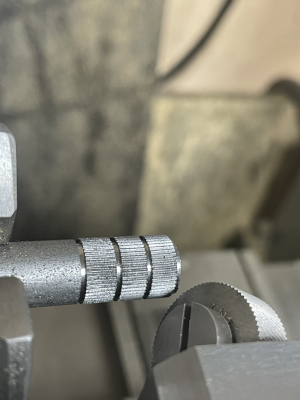

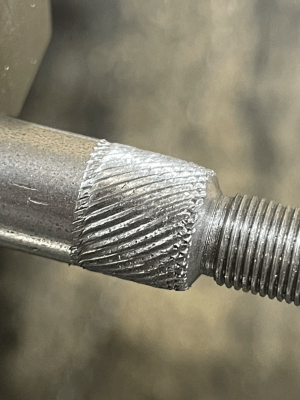

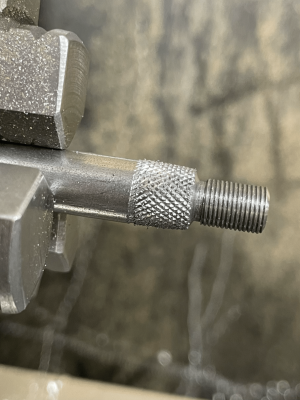

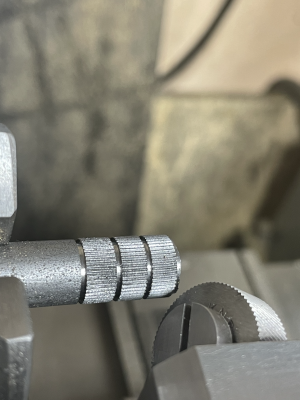

The knurls are the same ones I use with the Hemmingway sensitive knurler, they are 3/4"x1/4 wide with a 1/4" bore. I have a pair of 30 degree and a pair of straight wheels. To cut a straight knurl using a cut knurl, we use a spiral knurl wheel set over at the helix angle. To cut a spiral knurl, we use a straight knurl, set over at the helix angle. That sounds backward, but check out the photos and it may be clearer!

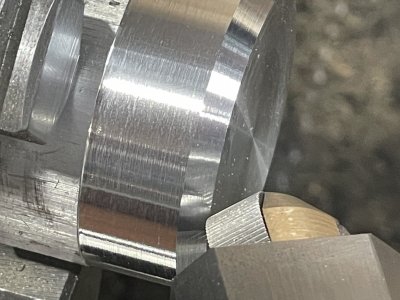

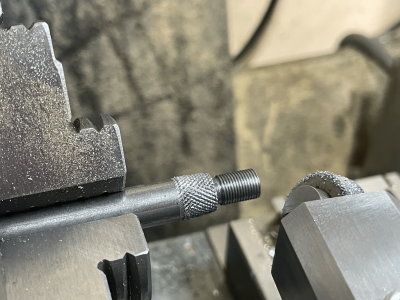

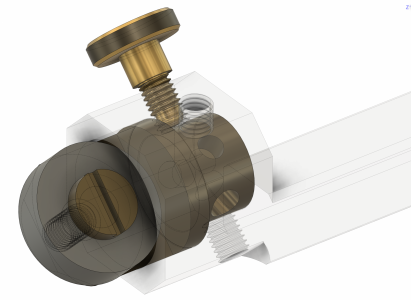

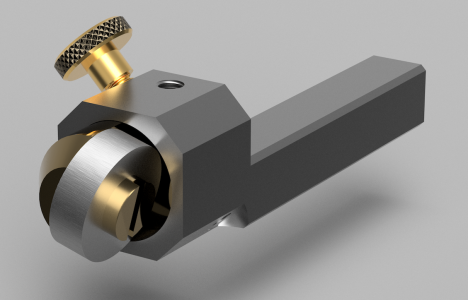

The idea is that the leading edge of the cut knurl wheel shears the material, whereas scissor knurling deforms the material. A knurl produced this way is the same diameter as the workpiece. To get this to work, the height of the knurl wheel must match the centreline of the work, which is handled by the toolholder adjustment, and the tool is set to a -2 degree rake, such that the leading edge of the knurl wheel cuts, while the trailing edge is in very light contact with the work. If the tool is square to the lathe centerline, the cutting action is slower and produces a rough surface.

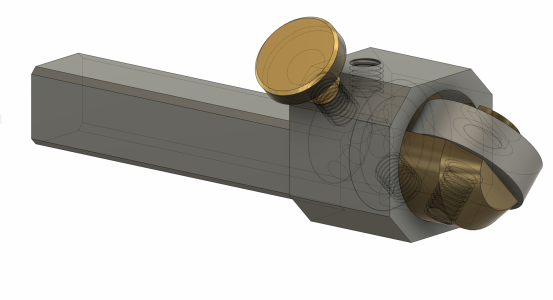

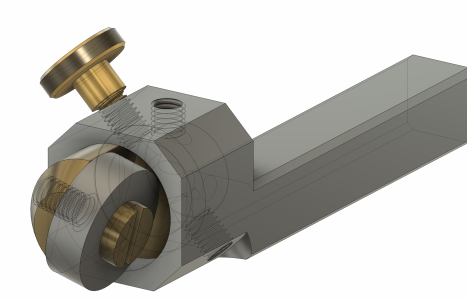

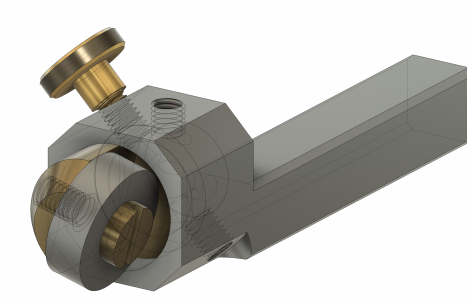

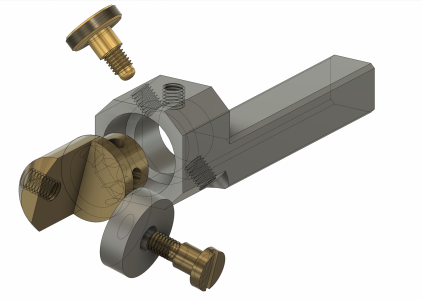

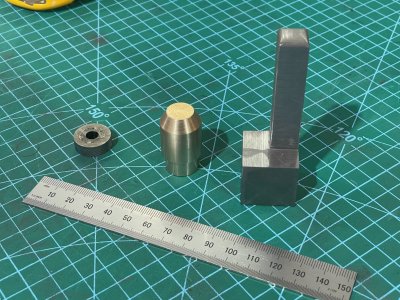

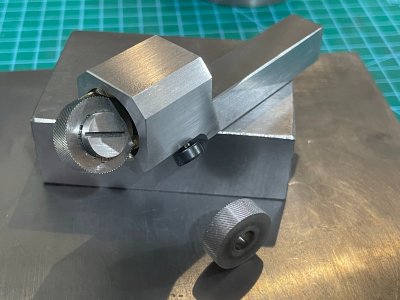

It started as a 4" long bar of 1" CRS. It was cut on the bandsaw to remove the unnecessary stuff, leaving an offset head and a 1/2" shank to fit the toolholder. The swivelling head is 3/4" bronze. It is indexed and locked firmly in place with the M5 screws. The head can be indexed to +/-45, +/-30 and vertical to suit the knurl wheel.

The knurls are the same ones I use with the Hemmingway sensitive knurler, they are 3/4"x1/4 wide with a 1/4" bore. I have a pair of 30 degree and a pair of straight wheels. To cut a straight knurl using a cut knurl, we use a spiral knurl wheel set over at the helix angle. To cut a spiral knurl, we use a straight knurl, set over at the helix angle. That sounds backward, but check out the photos and it may be clearer!

The idea is that the leading edge of the cut knurl wheel shears the material, whereas scissor knurling deforms the material. A knurl produced this way is the same diameter as the workpiece. To get this to work, the height of the knurl wheel must match the centreline of the work, which is handled by the toolholder adjustment, and the tool is set to a -2 degree rake, such that the leading edge of the knurl wheel cuts, while the trailing edge is in very light contact with the work. If the tool is square to the lathe centerline, the cutting action is slower and produces a rough surface.

It started as a 4" long bar of 1" CRS. It was cut on the bandsaw to remove the unnecessary stuff, leaving an offset head and a 1/2" shank to fit the toolholder. The swivelling head is 3/4" bronze. It is indexed and locked firmly in place with the M5 screws. The head can be indexed to +/-45, +/-30 and vertical to suit the knurl wheel.

Attachments

Last edited: