I need to replace my HSS end mills, they are all on their second sharpening and won't tolerate another sharpening attempt. I'm looking for 2 flute HSS nominal sizes 1/8, 1/4, 3/8, 1/2, 3/4.

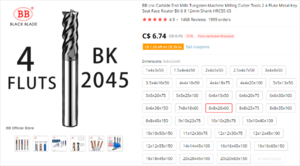

KBC branded end mills are more expensive than BB offerings and I really can't imagine they are any better in some way. I'm not seeing any smoking hot deals on AliExpress and everything there appears to be metric. Nothing much on Amazon for deals that I can see.

Where are you guys getting your end mills from?

Craig

KBC branded end mills are more expensive than BB offerings and I really can't imagine they are any better in some way. I'm not seeing any smoking hot deals on AliExpress and everything there appears to be metric. Nothing much on Amazon for deals that I can see.

Where are you guys getting your end mills from?

Craig