Marc Moreau

Marc Moreau

I am looking again for a variable speed press drill but I am scare about the electronic my Nova Voyager dvr did not work to long 2 or 3 year not to good service.

At my place I leave in residentiel place but I have no problem with neighbour's every body around are happy to see me. when they need me I'm there.

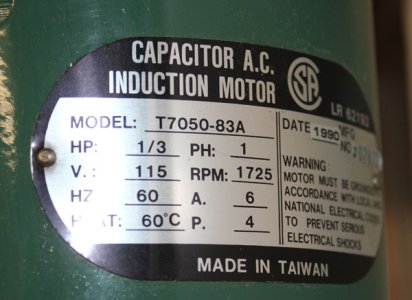

for the electricity is single phase 120 / 220 volts.

Leblond LTD have one LDP-25VS but I think that need 3 phase ? But is it good ?

Palmgren's have nice one with gear box I like that but I don't know if they have single phase ? and the price is around $ 8,318.00 US that's a lot of money.

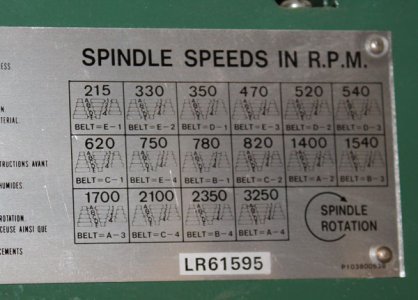

What I don't like about the belt drive you lost a lot's time to switch the belt . They are new model with a clutch that's nice but to get faster RPM you have to switch belt again but less time.

Any tip's or infos is very welcome. 1/8 drill 2500 RPM ? for steel 3/8 rpm for steel is 1000 and 1/2 drill for steel is 250

Most time I do all at 250 but with small drill on aluminium this is not good. Thank You

At my place I leave in residentiel place but I have no problem with neighbour's every body around are happy to see me. when they need me I'm there.

for the electricity is single phase 120 / 220 volts.

Leblond LTD have one LDP-25VS but I think that need 3 phase ? But is it good ?

Palmgren's have nice one with gear box I like that but I don't know if they have single phase ? and the price is around $ 8,318.00 US that's a lot of money.

What I don't like about the belt drive you lost a lot's time to switch the belt . They are new model with a clutch that's nice but to get faster RPM you have to switch belt again but less time.

Any tip's or infos is very welcome. 1/8 drill 2500 RPM ? for steel 3/8 rpm for steel is 1000 and 1/2 drill for steel is 250

Most time I do all at 250 but with small drill on aluminium this is not good. Thank You