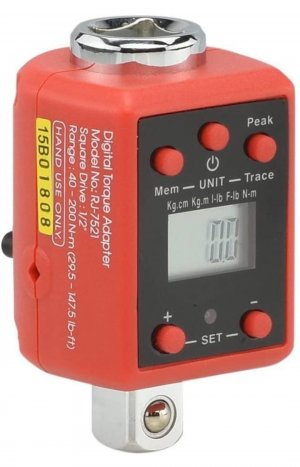

FYI most of the electronics ones are good because they are based on simple yet effective strain gauge circuits. The difference between cheap and expensive is only on how long the display side of the circuitry lasts.

I confess that I am surprised by this statement. I certainly agree that they are probably strain gauge based. I don't know that for sure though. Regardless, I'd love to know how the heck you know that the difference between expensive and cheap is only on how long the display side works?

What about AD conversion, temp compensation, calibration, significant digits, rounding, averaging, truncation, component grade, sealing, adhesives, material choice, etc etc.

I spent a large part of my career doing sensor systems design. I've learned not to trust digital anything. Far too much of that work was done by electrical or software people who don't understand mechanical or electro mechanical systems. The process and accuracy of converting a mechanical signal to an analog signal and then from analog to digital is much more complicated than most people know. The circuitry, components, and subsequent design choices made when analysing, processing, and computing those digital signals and presenting them for display provides yet another opportunity for things to go south. For me at least, familiarity breeds contempt.

Perhaps I've gone on this rant too much already, but please allow me to give an example. Almost everyone has a bathroom scale - most of which are also based on strain gauge technology. All I can do is laugh while my wife panics over her daily gains and losses. I've tried to tell her it's just the scales but she ignores me. But you try it! Just get on and off three or more times and compare the numbers. Better yet, weigh a given thing (say a 5 Gal pail of sand or gravel) 3 times a day over the course of a few weeks, record the numbers, and then assess how you feel about the accuracy of that scale. The balance beam at the doctors office will be dead nuts and your old spring based home scale will be ok. Your new digital scale will most likely suck.

I love digital as much as anyone, but I don't automatically trust it. For me, that trust must be earned - not simply given.

Rant over for today. Sorry about that. Please don't take offense to anything said above. It's all just me going on my favorite anti-digital rant.

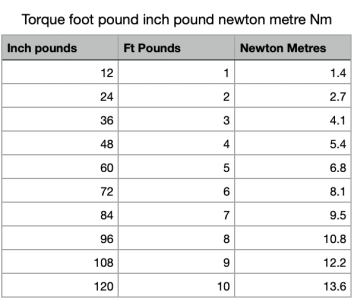

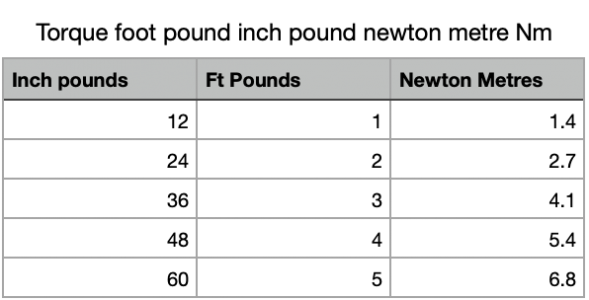

For what it's worth, I am going to get one of those torque gauges you recommended and try it. I do a LOT of low torque work. I would love to find a reliable digital way to set and measure low torques.

Lord knows I've spent a small fortune on small digital weigh scales. They are all gathering dust. The only thing I trust is an old mechanical balance beam.