No, but I've monkeyed around with several makeshift gadgets that attempted to do the same thing I'm almost wishing I bit the bullet. The thought of loosening & displacing my nicely dialed in tailstock for taper turning is about as appealing as removing my mill vise & changing my spindle nod & tilt while I'm at it. They are all reposition-able but it takes time to get back in alignment again. I acquired a small diamter boring head that I might press into service.

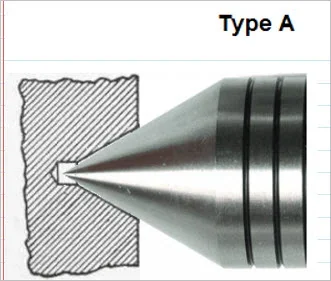

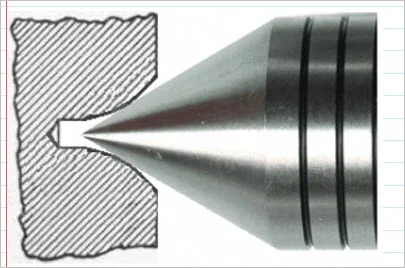

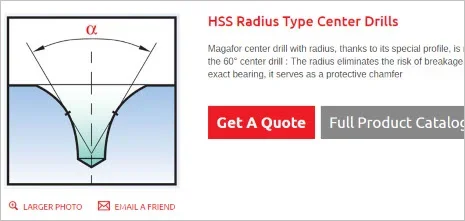

One thing to know about those offset methods you don't read about often. Technically you should be drilling the center hole in the part with a bellmouth curved profile as opposed to the straight 60-deg profile we all have. Two cones don't make a right HaHa. Turns out these profiles aren't exactly abundant, probably because most people (unlike me & apparently you too) got a legitimate taper attachment. I suspect for shallow tapers it might not be the end of the world. But I think why some people spec certain kinds of high temp grease or tip get shot is due to this.