-

Spring 2024 meetup in Calgary - date Saturday, April 20/2024. discussion Please RSVP Here to confirm and get your invitation and the location details. RSVP NOW so organizers can plan to get sufficient food etc. It's Tomorrow Saturday! you can still RSVP until I stop checking my phone tomorrow More info and agenda

-

We are having email/registration problems again. Diagnosis is underway. New users sorry if you are having trouble getting registered. We are exploring different options to get registered. Contact the forum via another member or on facebook if you're stuck. Update -> we think it is fixed. Let us know if not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Relocation of oiler port

- Thread starter DPittman

- Start date

Yes I forgot to mention that there is likely a channel on the underneath that I could just drill up from the bottom to make sure I get in it. I've had it all apart but I just don't remember exactly what it looked like underneath there.In my experience with oil holes they are sometimes located to feed into a channel or line that takes oil to where it is required. I would take it apart and see how it is constructed.

I think that may have been an option (certainly was with other suppliers) but I have already purchased this DRO 6+months ago and so am going to make it work. I'm just contemplating all the options now.Does the DRO manufacturer offer a slim magnetic scale?

If you are going to drill I would be taking it apart and to check it can be done and to prevent swarf from getting into the lubrication system. Cast iron is nasty stuff.Yes I forgot to mention that there is likely a channel on the underneath that I could just drill up from the bottom to make sure I get in it. I've had it all apart but I just don't remember exactly what it looked like underneath there.

I cannot tell from the picture, does the scale sit right on top of the carriage and cover the oiler? If there is room between the scale and the compound could a oil line be inserted into the oiler hole?

It might be easier to just buy a slimmer scale and sell or re-purpose the other one.

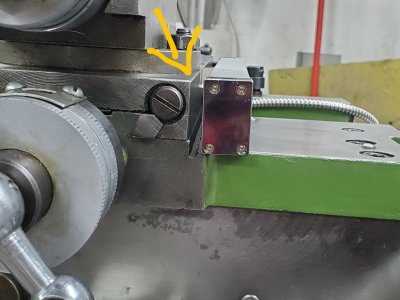

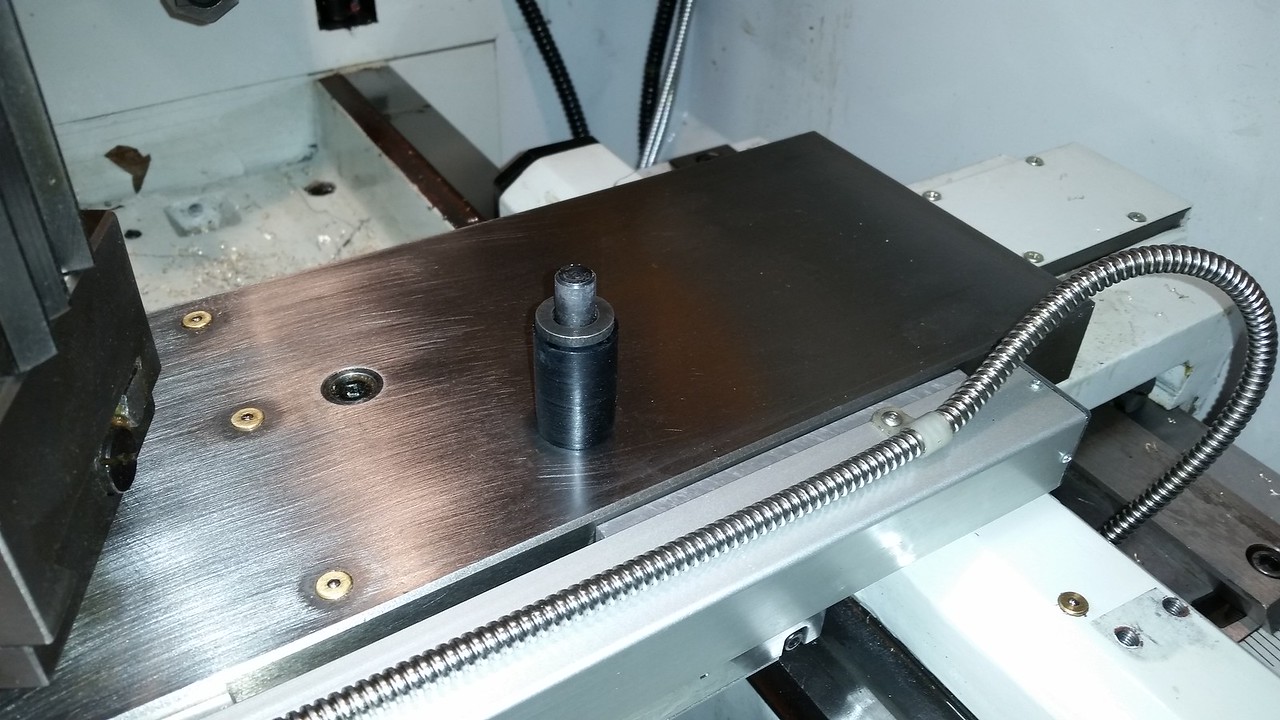

I'm going to be installing a DRO on a lathecross slide but the way I think the scale should be mounted blocks an oiler port. Drilling a new hole in the saddle and popping in a new oiler port in a different location shouldn't be a big deal right? I'll just plug the old hole.

I'm voting in favour of a slim scale. I believe they are identical to the regular magnetic scales in terms of the strip characteristics. I think just the carrier extrusion is bigger and stronger. Somebody on here will know for sure. Regardless, I'll be following what you do very closely with this. As they say...... You go first!

That said, your issues and a dozen others are what drove me to love @Xyphota 's solution of burying the scale inside the compound.

See my thoughts on this approach in my thread 'Lathe DRO w Buried Scale' https://canadianhobbymetalworkers.com/threads/lathe-dro-w-buried-scale.6094/

Dang it you guys! Don't go convincing me I need to buy new scales, it can't happen.

Just because I am not willing to follow your advice doesn't mean I don't value it. I do value all the advice immensely.

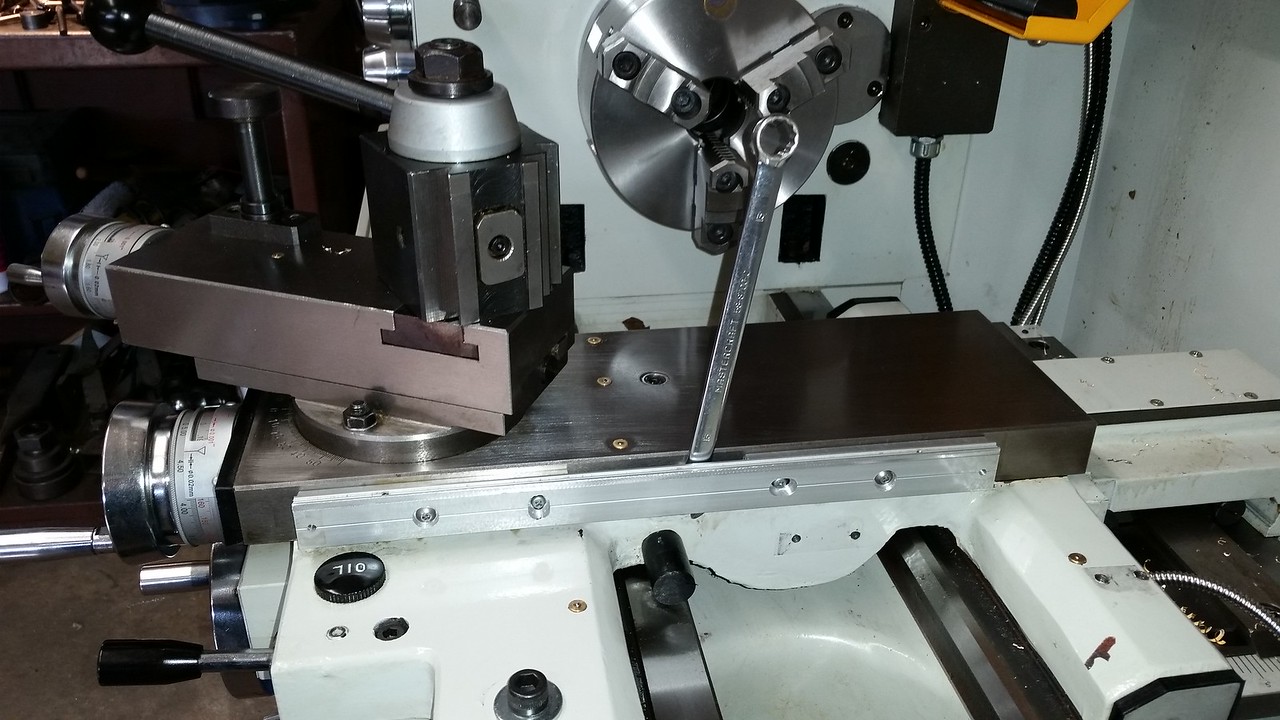

The slim scale solution would definitely easily solve the oiler port problem but I think I'm going to be okay afterall but it will be close. I also have to mount the scale away from the cross slide surface to allow access to the slide lock. Traveling rest mount on the carriage keeps me from installing the scale on the opposite side (plus I don't want scale under the chuck).

Traveling rest mount on the carriage keeps me from installing the scale on the opposite side (plus I don't want scale under the chuck).

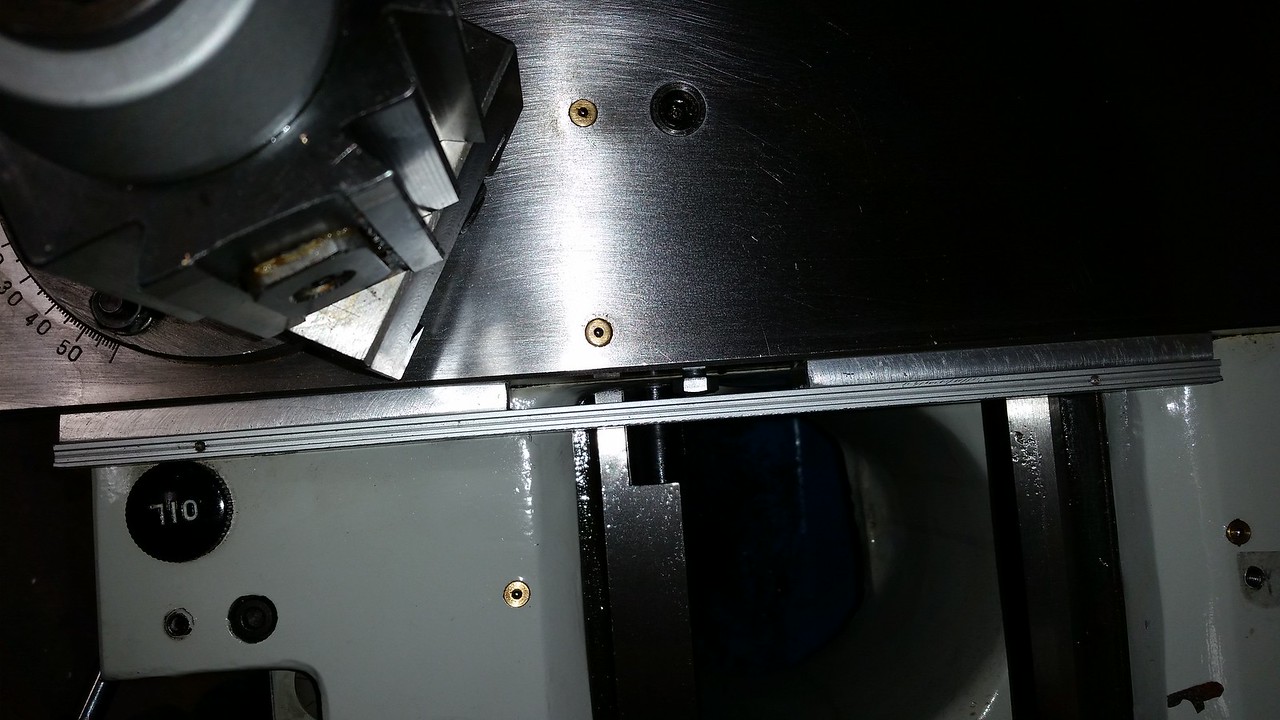

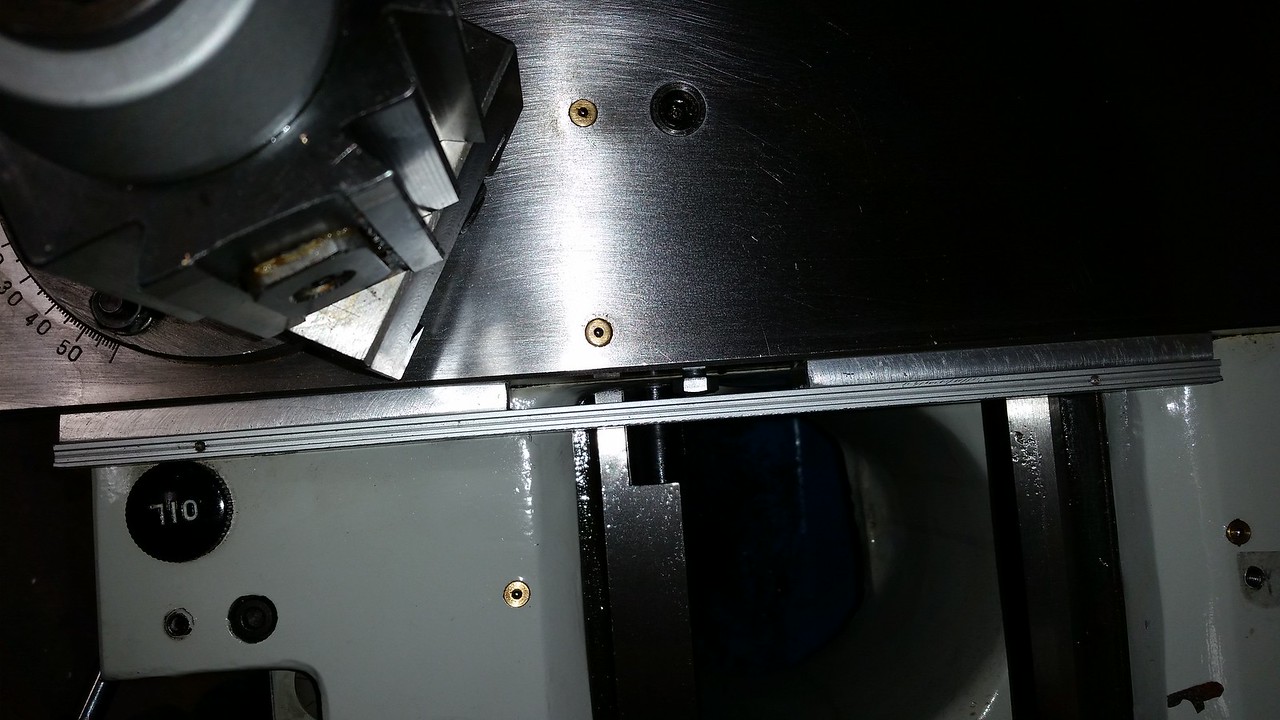

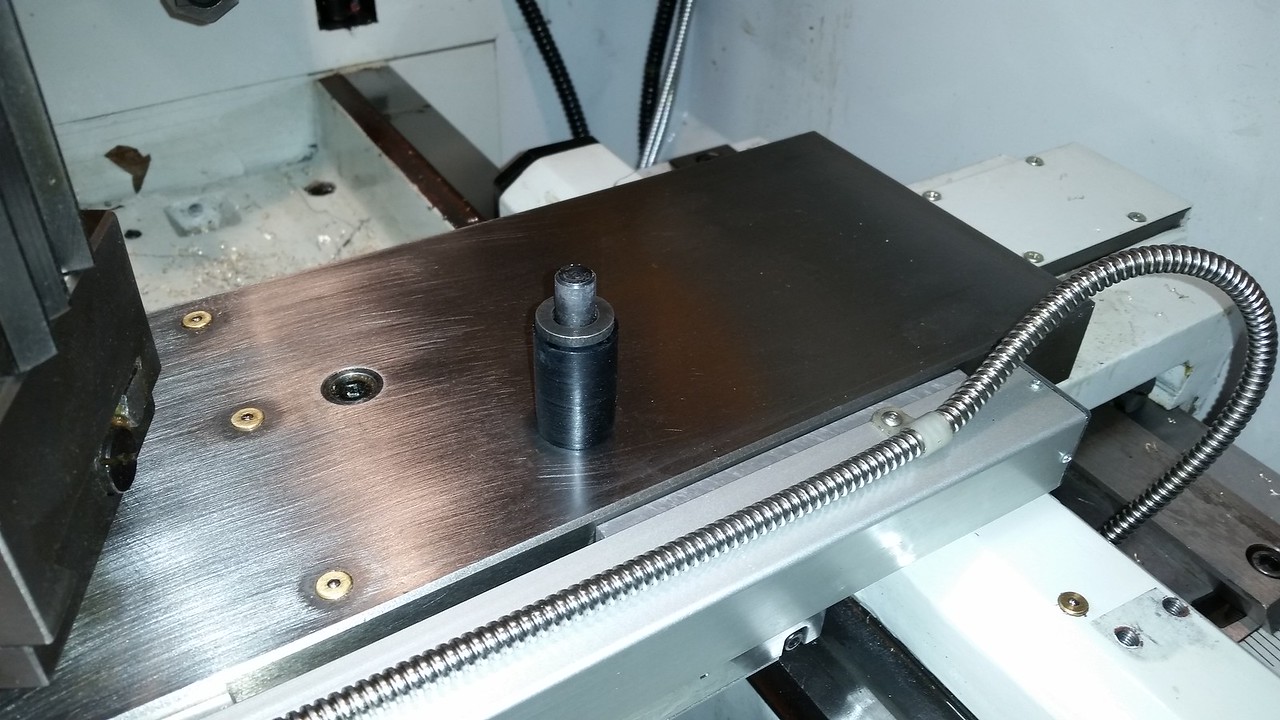

My next obstacle is mounting the scale brackets into the slide surface as their is very little meat to drill and tap into as the gib adjustment runs along that side. See pic.

So now I'm wondering if JB welding mounts to the slide surface is likely to be satisfactory?

Just because I am not willing to follow your advice doesn't mean I don't value it. I do value all the advice immensely.

The slim scale solution would definitely easily solve the oiler port problem but I think I'm going to be okay afterall but it will be close. I also have to mount the scale away from the cross slide surface to allow access to the slide lock.

My next obstacle is mounting the scale brackets into the slide surface as their is very little meat to drill and tap into as the gib adjustment runs along that side. See pic.

So now I'm wondering if JB welding mounts to the slide surface is likely to be satisfactory?

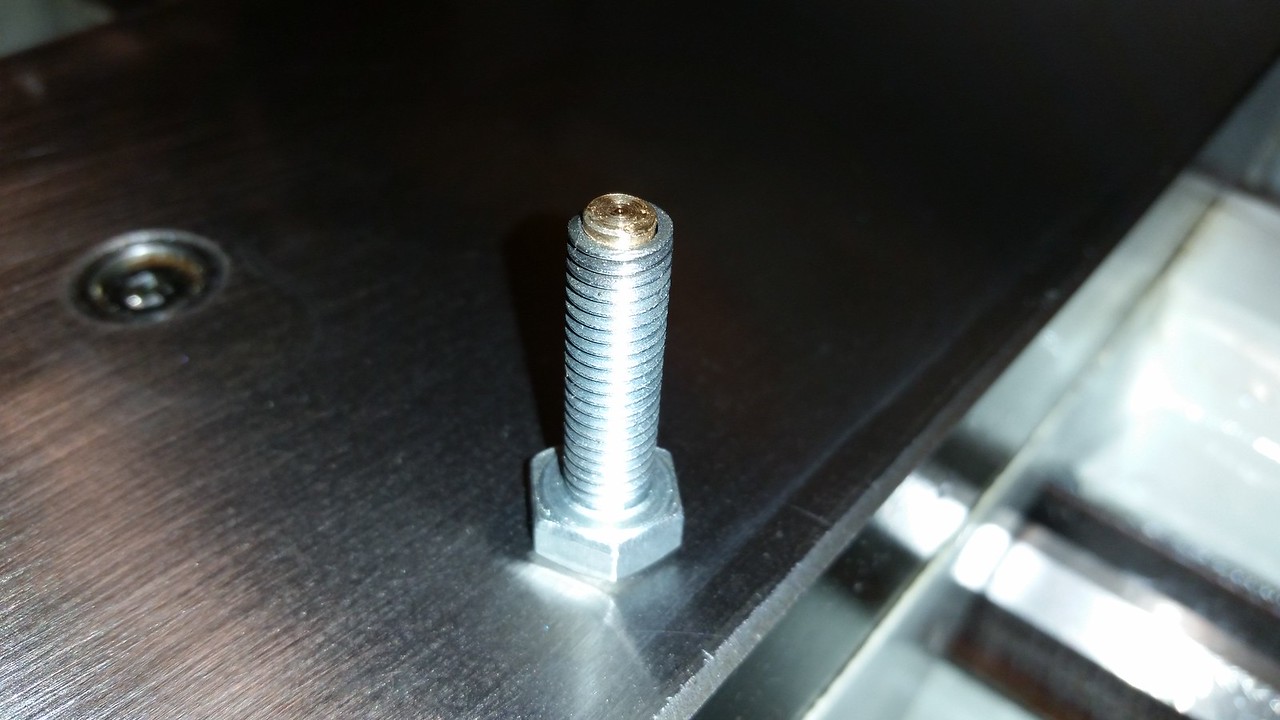

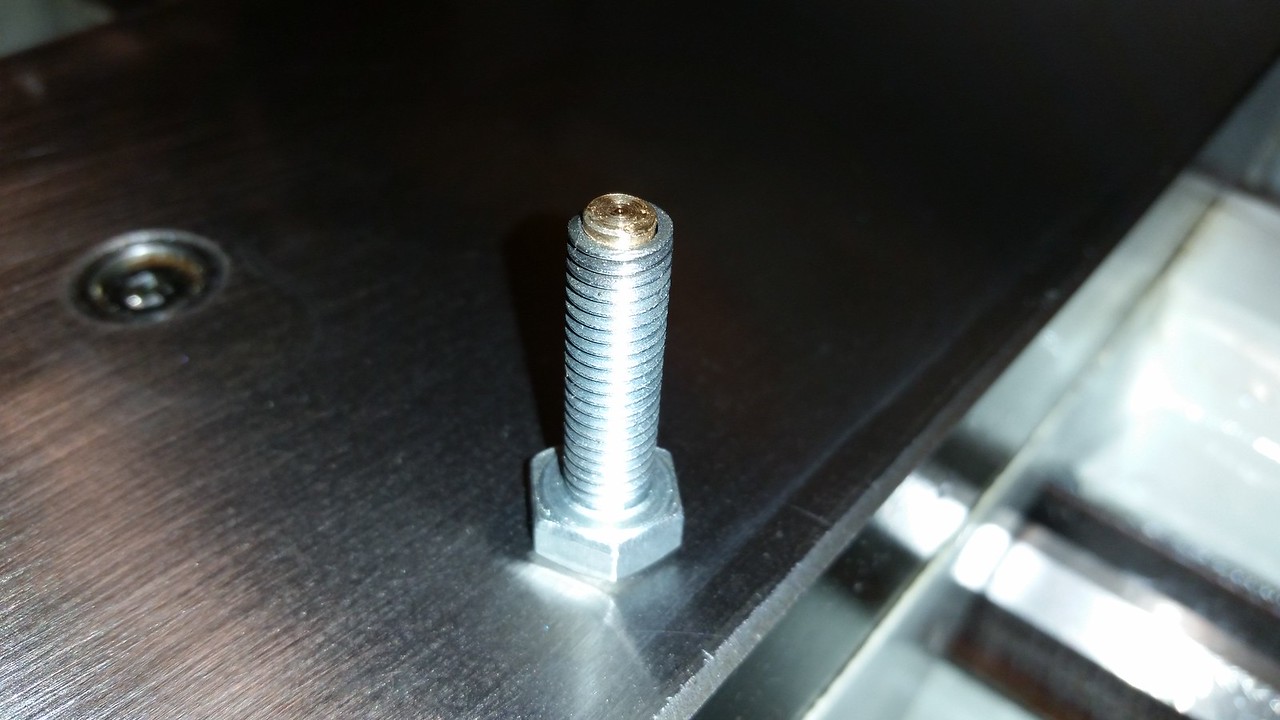

Drilling a new oiler hole should be no issue but assembly will have to be removed so you don't over drill into the bed. When see the underside you can verify channel or no channel in which case yes you should connect it. But it its like my Taiwan 14x40 lathe, those ports just dead end to bed way. Which is why there is so much back pressure on an oiler using higher viscosity way oil & it makes a localized puddle instead of nice distribution.

Oilers vary in quality so I would have those in hand beforehand. What they call a 6mm body may correspond to a slightly different drill to make it press in properly. If its loose that's no good, it will probably hydraulically lift with pressure. Ie. so try it on a practice chunk of steel before your lathe. I had a lead on the higher quality 'red dot' euro ones Stefan used but they were PITA to order. i should have perservered, this topic has come up so many times.

Oilers vary in quality so I would have those in hand beforehand. What they call a 6mm body may correspond to a slightly different drill to make it press in properly. If its loose that's no good, it will probably hydraulically lift with pressure. Ie. so try it on a practice chunk of steel before your lathe. I had a lead on the higher quality 'red dot' euro ones Stefan used but they were PITA to order. i should have perservered, this topic has come up so many times.

I would not recommend adhesive for any kind of DRO mounting unless you mean to temporarily attach so you can better drill/tap holes or back fill a slight unconformity. Its better to bolt it together mechanically. Odds are you may have to dismantle lathe/DRO in the future for whatever reason & then whacking off glued parts wont be fun.

I showed some pics of my scale on LHS of cross slide to avoid gib strip. If you protect it properly with a guard, its not a big deal. But you might lose the functionality of mounting a travelling steady so there are pros & cons that only you can answer for yourself. Do you have a table lock on the RHS that the scale will cover up for example?

I showed some pics of my scale on LHS of cross slide to avoid gib strip. If you protect it properly with a guard, its not a big deal. But you might lose the functionality of mounting a travelling steady so there are pros & cons that only you can answer for yourself. Do you have a table lock on the RHS that the scale will cover up for example?

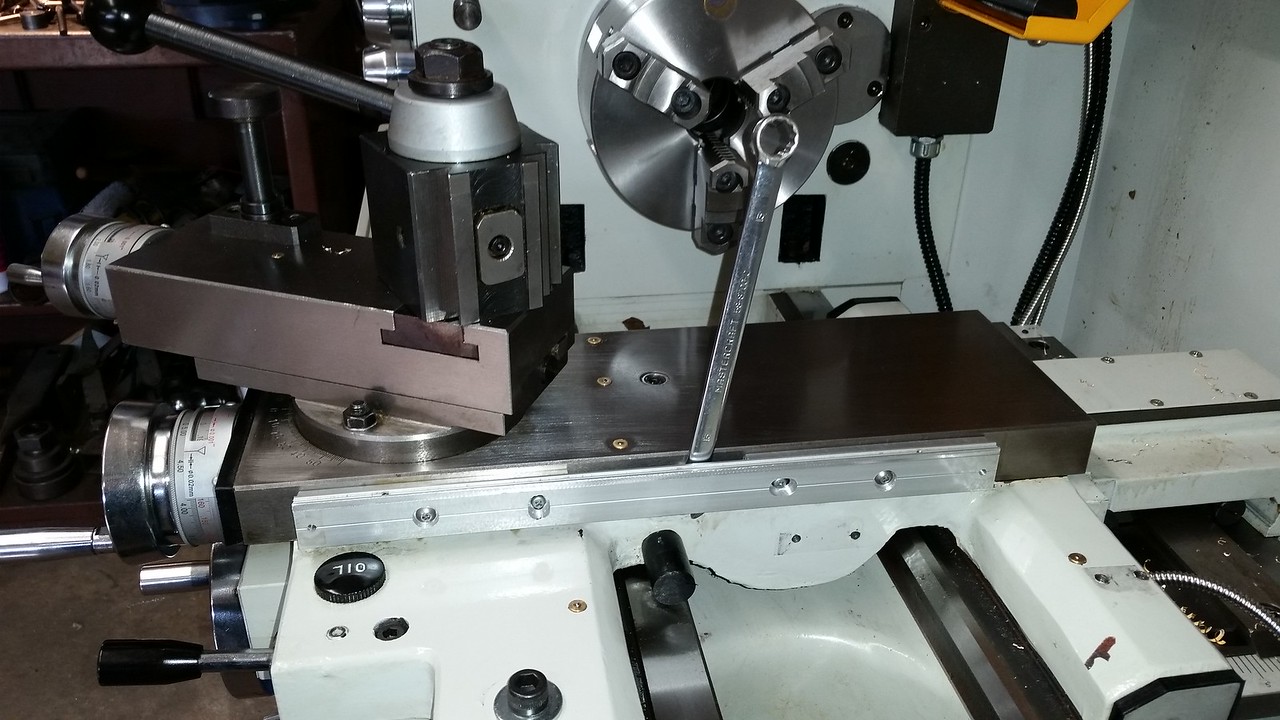

It looks like your gib strip is right at the bottom surface of the cross slide. If you remove that gib adjusting screw you'll see how tall it is and drill your screw holes above it. I agree with the others, I would remove the cross slide to drill the new oiler hole. You really don't need to make a plug for the old one, just leave it where it is. I made 3/8" thick spacers to move the cross slide scale outward so I could access the lock screw with an open end wrench. I added a brass insert to the end of the screw and made it just long enough to lock the cross slide when fully threaded in.Dang it you guys! Don't go convincing me I need to buy new scales, it can't happen.

Just because I am not willing to follow your advice doesn't mean I don't value it. I do value all the advice immensely.

The slim scale solution would definitely easily solve the oiler port problem but I think I'm going to be okay afterall but it will be close. I also have to mount the scale away from the cross slide surface to allow access to the slide lock.Traveling rest mount on the carriage keeps me from installing the scale on the opposite side (plus I don't want scale under the chuck).

My next obstacle is mounting the scale brackets into the slide surface as their is very little meat to drill and tap into as the gib adjustment runs along that side. See pic.View attachment 27618

So now I'm wondering if JB welding mounts to the slide surface is likely to be satisfactory?

My first feelings about JB welding attachment is well, "it's sort of Mickey Mouse-ish" but I haven't been able to completely rule it out yet.I would not recommend adhesive for any kind of DRO mounting unless you mean to temporarily attach so you can better drill/tap holes or back fill a slight unconformity. Its better to bolt it together mechanically. Odds are you may have to dismantle lathe/DRO in the future for whatever reason & then whacking off glued parts wont be fun.

I showed some pics of my scale on LHS of cross slide to avoid gib strip. If you protect it properly with a guard, its not a big deal. But you might lose the functionality of mounting a travelling steady so there are pros & cons that only you can answer for yourself. Do you have a table lock on the RHS that the scale will cover up for example?

I would only glue the one side of the bracket to the slide surface, so if I ever had to dismantle it would not be a big deal.Odds are you may have to dismantle lathe/DRO in the future for whatever reason & then whacking off glued parts wont be fun.

Yes I have a table lock on the rhs, but I should be able to get the scale in just before the two obstacles. But i wont be able to have the cover over the scale. And no I don't want to loose the ability to use a steady restDo you have a table lock on the RHS that the scale will cover up for example?

on the front side. At least that's my latest thinking. See pic.

on the front side. At least that's my latest thinking. See pic.Yes that is pretty much what I was thinking also in regards to accessing the table lock also.It looks like your gib strip is right at the bottom surface of the cross slide. If you remove that gib adjusting screw you'll see how tall it is and drill your screw holes above it. I agree with the others, I would remove the cross slide to drill the new oiler hole. You really don't need to make a plug for the old one, just leave it where it is. I made 3/8" thick spacers to move the cross slide scale outward so I could access the lock screw with an open end wrench. I added a brass insert to the end of the screw and made it just long enough to lock the cross slide when fully threaded in.

In your last picture I see the cable running up on top, is that for the reader head on that scale? I'm thinking I'm going to mount the reader head down below the scale and run the cable out back.

Dang it you guys! Don't go convincing me I need to buy new scales, it can't happen.

OK, but 1 meter of tape is only $25 US Plus Shipping. IT CAN HAPPEN! Just think about the beauty of a buried Scale...... So make it happen! Then show me how you did it..... LOL!

AIKRON MS50 MAGNETIC TAPE - Sichuan Aikron Precision Tool Co.,Ltd

Magnetic tape are important if you want your magnetic scale system to work out an excellent accuracy,they are the key to contrubute accuracy.

I would not recommend adhesive for any kind of DRO mounting unless you mean to temporarily attach so you can better drill/tap holes or back fill a slight unconformity.

For the most part I agree with you Peter. And that's how all mine are done.... till now.

However, the magnetic strip is already just adhesive taped to the scale extrusion. If the surface you are mounting the scale to is flat, using the tape the strip comes with, makes great sense. If the strip ever has to be removed, you just pull it off and then scrape the tape off. The magnetic strip won't be any good anymore anyway. But it should not ever need to be removed cuz it's not gunna ever be in the way.

I originally got this direct mount idea for the tape from @Dabbler. As soon as I read it, my mind snapped shut like a steel trap. It's almost a no-brainer.

But I agree, I'm not in favour of gluing the scale extrusion to anything on a permanent basis.

FWIW. I never suggested gluing the scale extrusion, just the mounting brackets that the extrusion will bolt onto.But I agree, I'm not in favour of gluing the scale extrusion to anything on a permanent basis.

FWIW. I never suggested gluing the scale extrusion, just the mounting brackets that the extrusion will bolt onto.

I know. I was really just refining Peter's comments.

FWIW, my very first scale mount (and last) was done with double sided tape for test fitting like recommended by DRO PROS. I'll NEVER do that again...... I don't even want that stuff in there temporarily!

However, I did make levelling posts/pads out of epoxy for the knee scale on my mill. No other way to get it level and square to the read head travel.

So I gather you are gunna make me go first...... I forsee a drop dead gorgeous cross-slide scale install. I'll send you a PM when it's done so you can cry..... LOL! Might be a while though!

I'll buy a meter of magnetic tape now so I can test it and be ready when the time comes to buy my next DRO. I also need to look real hard at the back of my lathe bed. A tape on scale might work great there too.

Well who knows when I will finish this job as it's kind of low priority. I had no idea when I got out of bed this morning that I would be starting this project today. It was a "diversion" project for the day to forget about some of lifes real problems.So I gather you are gunna make me go first...... I forsee a drop dead gorgeous cross-slide scale install. I'll send you a PM when it's done so you can cry..... LOL! Might be a while though!

I look forward to seeing your install, it sounds like it will be nice.

It was a "diversion" project for the day to forget about some of lifes real problems.

Boy do I get that. I find my shop activities to be very therapeutic - especially when I'm really down.

I just measured my bed. 1 meter of tape won't do my cross-slide AND my bed. So I'll have to order 2 meters and that means I'll have enough tape to do your cross-slide too if you want it. I'll prolly order tomorrow or Monday.