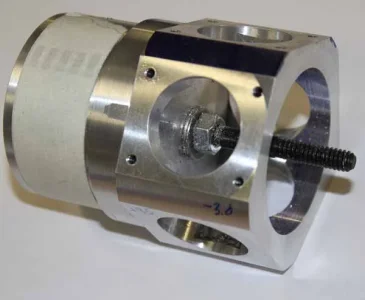

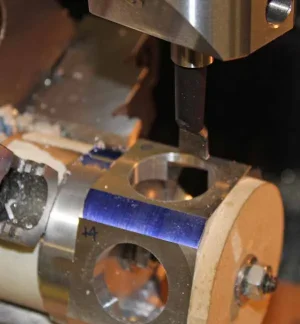

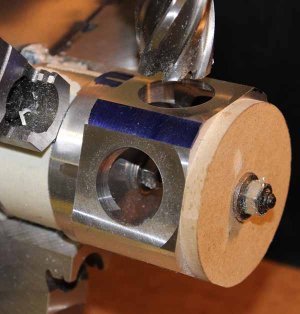

Some of you have seen my cylinder parts work in progress. Now I'm proceeding on the center guts, specifically the crankcase. I have not done this sort of work before & figured there would probably be some learning's.... and there were  Actually operations went quite smooth, so I figured I was going to be 'that guy' who broke his tap off in he proverbial 'last hole'. Turns out I had a more fundamental problem.

Actually operations went quite smooth, so I figured I was going to be 'that guy' who broke his tap off in he proverbial 'last hole'. Turns out I had a more fundamental problem.

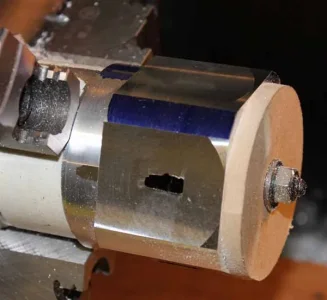

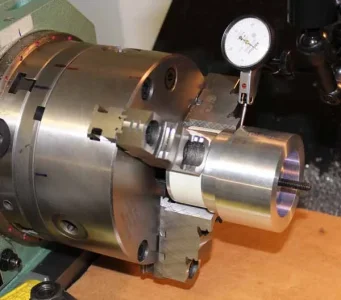

I dialed the donut block in longitudinally + square + #1 cylinder clock orientation, but completely mind blanked to check the concentricity with RT axis. My chuck is a 3-jaw with centering plate & jaws presumably pretty accurate. Never assume! I'm not sure if the setup shifted and/or the typical 3-jaw clamping runout. But anyway some deck facets are off by max ~ 4-5 thou depending on the cylinder. Actually I could tell something was up when the internal master rod groove started breaking through unequally, which I wishfully hoped was just out-of-round grooving induced back at the lathe stage.

4-5 thou may not sound like much but it is. Unfortunately this translates into each cylinder sitting at a different deck height resulting in different compression ratio's on each cylinder. I don't want to mess with custom cylinders or modified pistons, that just gets nutty. So.... #1 is a Binner! No biggy actually, now I feel quite confident about #2 and having a spare tester is for other operations is nice.

Tooling Opinion:

I've never been super keen on my 6" 3-jaw on 6" RT combo. Its big & heavy & extended stick-out for my needs. More importantly it really doesn't lend itself to dialing in. Even good 3-jaw chucks can have 2-3 thou runout & this may vary depending on part diameter as a function of the scroll. This particular plate assembly relies on a centering do-dad & nestled registration bosses. Seemed like a smart choice convenience wise, but sources of collective error creep. So, I've ordered a smaller 4-jaw chuck (offshore Asian, fingers crossed) and will have to make an adapter plate. But if it goes according to plan I'll have a an assembly that is much easier to mount, adjust & zero part concentricity. Plus 4-jaws can hold irregular stock..

I dialed the donut block in longitudinally + square + #1 cylinder clock orientation, but completely mind blanked to check the concentricity with RT axis. My chuck is a 3-jaw with centering plate & jaws presumably pretty accurate. Never assume! I'm not sure if the setup shifted and/or the typical 3-jaw clamping runout. But anyway some deck facets are off by max ~ 4-5 thou depending on the cylinder. Actually I could tell something was up when the internal master rod groove started breaking through unequally, which I wishfully hoped was just out-of-round grooving induced back at the lathe stage.

4-5 thou may not sound like much but it is. Unfortunately this translates into each cylinder sitting at a different deck height resulting in different compression ratio's on each cylinder. I don't want to mess with custom cylinders or modified pistons, that just gets nutty. So.... #1 is a Binner! No biggy actually, now I feel quite confident about #2 and having a spare tester is for other operations is nice.

Tooling Opinion:

I've never been super keen on my 6" 3-jaw on 6" RT combo. Its big & heavy & extended stick-out for my needs. More importantly it really doesn't lend itself to dialing in. Even good 3-jaw chucks can have 2-3 thou runout & this may vary depending on part diameter as a function of the scroll. This particular plate assembly relies on a centering do-dad & nestled registration bosses. Seemed like a smart choice convenience wise, but sources of collective error creep. So, I've ordered a smaller 4-jaw chuck (offshore Asian, fingers crossed) and will have to make an adapter plate. But if it goes according to plan I'll have a an assembly that is much easier to mount, adjust & zero part concentricity. Plus 4-jaws can hold irregular stock..