On another subject, Darrin1200 posted a link to this (Canadian) company https://www.penblanks.ca/

That kind of perked my interest. I've been kind of interested to dabble in this area, nothing too crazy, maybe an occasional family gift. I'm guessing aside from the body stock material & pen/pencil innards kit, I likely have typical finishing supplies in my shop. I'm sure there are 100 YouTube videos I should be absorbing, but just wondering if there are some forum folks doing this? I'm sure I've seen some nice project pics. Feel free to post or attach links.

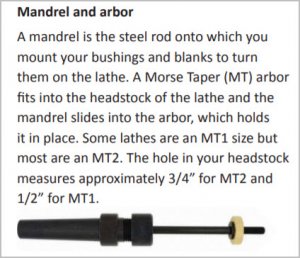

Looking at some of their beginner how-to guides, they show some mandrels, typically MT1,MT2. So guessing this corresponds to smaller lathes like Sherline, TAIG etc? So if I want to use my regular (14x40) lathe, would I use the straight shank [PKM-CL fits 5/8” diameter (no thread)] or make my own?

https://www.penblanks.ca/instructions/english/Penturning101ENG.pdf

That kind of perked my interest. I've been kind of interested to dabble in this area, nothing too crazy, maybe an occasional family gift. I'm guessing aside from the body stock material & pen/pencil innards kit, I likely have typical finishing supplies in my shop. I'm sure there are 100 YouTube videos I should be absorbing, but just wondering if there are some forum folks doing this? I'm sure I've seen some nice project pics. Feel free to post or attach links.

Looking at some of their beginner how-to guides, they show some mandrels, typically MT1,MT2. So guessing this corresponds to smaller lathes like Sherline, TAIG etc? So if I want to use my regular (14x40) lathe, would I use the straight shank [PKM-CL fits 5/8” diameter (no thread)] or make my own?

https://www.penblanks.ca/instructions/english/Penturning101ENG.pdf