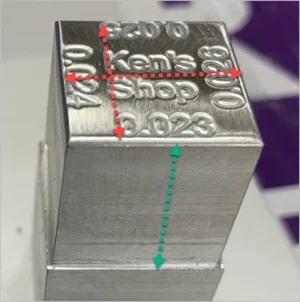

my buddy Ken who is a woodworking expert needed a block for measuring saw blade offsets for dovetail making. He had a design which I executed today. I got it to within a thou or so on each side of the block. The idea is the step down is 0.023 on one side 0.024” on the next etc. The results are ok but i would have been happier with 2 tenths accuracy not a thou.

I milled it vertical in the vise with a 3/4EM milling off the sides to depth. Question if I instead laid the part sideways and face milled the depth would it be more accurate? How could I mill this more accurately?

I milled it vertical in the vise with a 3/4EM milling off the sides to depth. Question if I instead laid the part sideways and face milled the depth would it be more accurate? How could I mill this more accurately?