Canadium

Ian

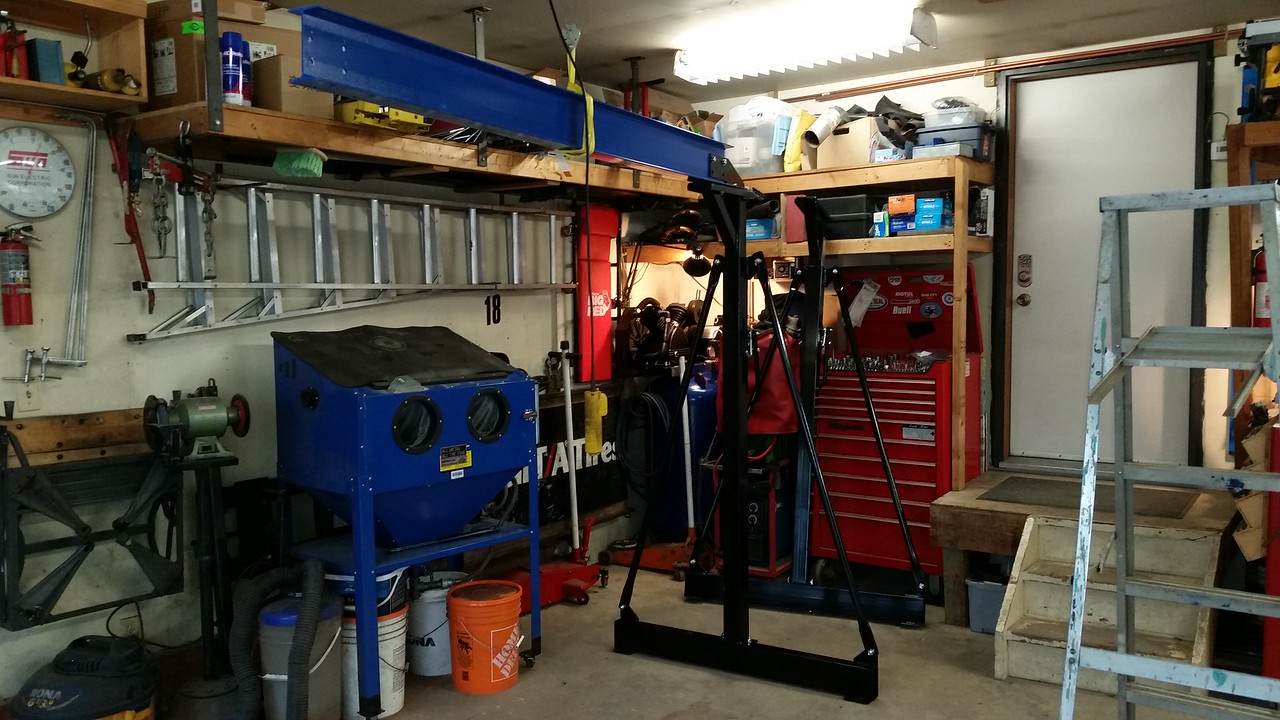

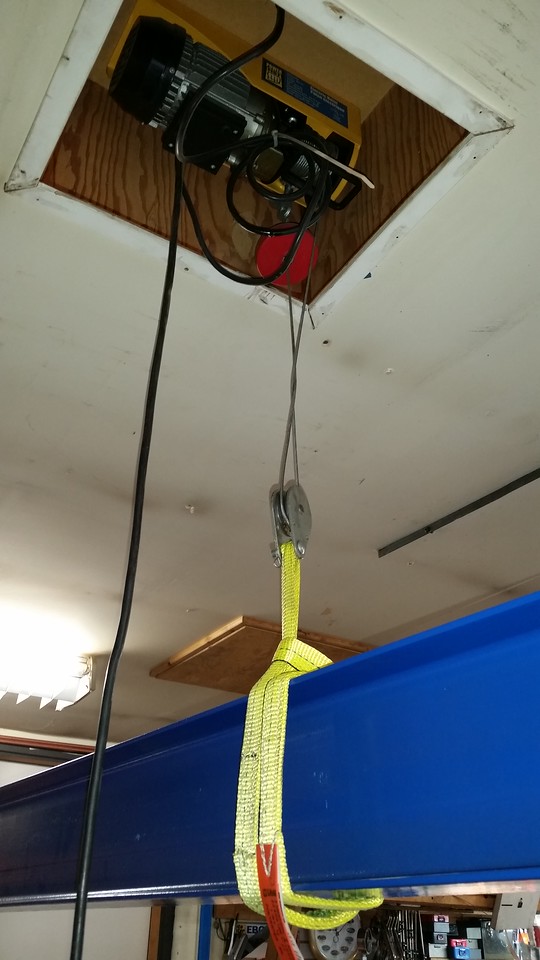

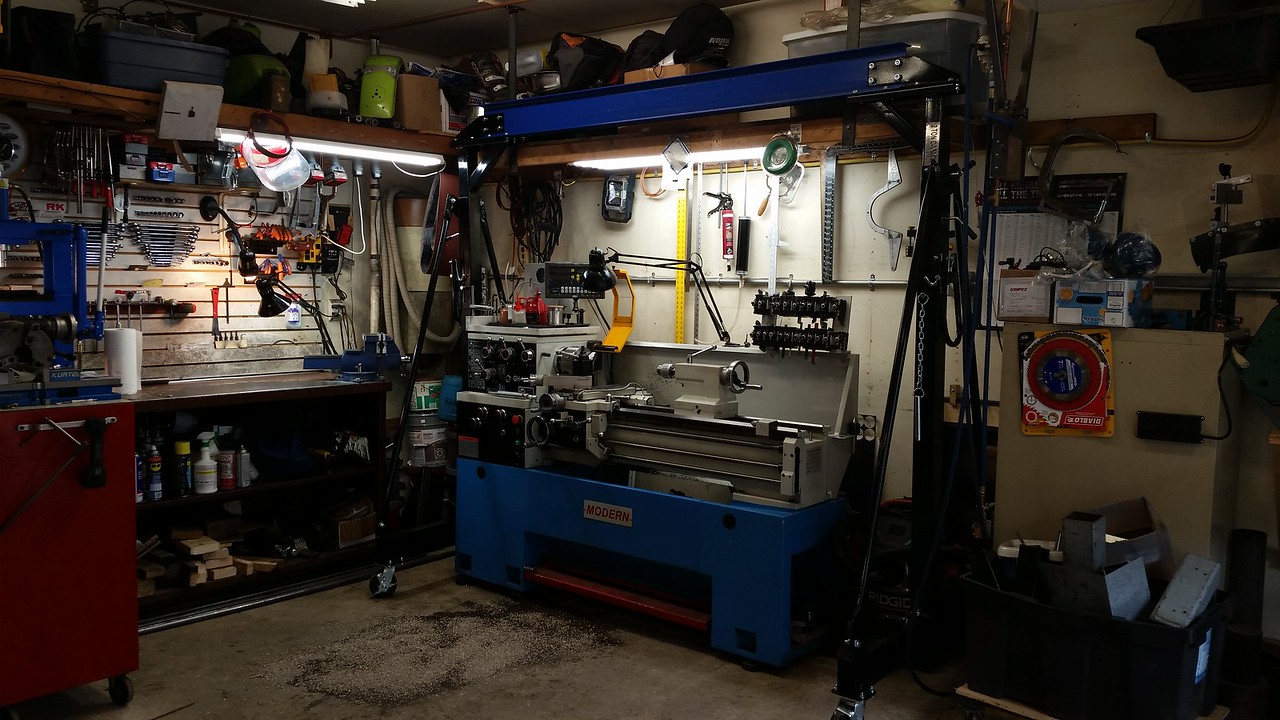

So when Princess Auto put their 2 ton gantry on sale last week for $800 I couldn't resist. I brought one home. I would wager you couldn't buy the steel to make your own at that price. I just discovered however that whereas their 1 ton gantry is a fairly easy 1 person assembly project the 2 ton is a challenge! All parts on the 2 ton are a lot heavier and the overhead beam is close to the limit of what one person can manhandle. I was fine getting the first vertical post attached but attaching the second safely was hard without special equipment or additional helpers. I ended up using my engine crane to lift it part way and manhandled it the rest of the way onto a temporary scaffold I made out of scrap lumber. The scaffold held the second upright in place and provided a wider more stable target for the beam to rest on before it was aligned and attached.

It was so much trouble getting the thing together I can't see myself keeping this disassembled for storage and putting it together again every time I need it. The assembly is close to permanent and will have to stay outside to brave the elements. So I expect to make some kind of plastic envelope around it to protect it from the elements. The thing has about 60 bolts in total so not designed to be easily dismantled for storage as far as I can see.

It was so much trouble getting the thing together I can't see myself keeping this disassembled for storage and putting it together again every time I need it. The assembly is close to permanent and will have to stay outside to brave the elements. So I expect to make some kind of plastic envelope around it to protect it from the elements. The thing has about 60 bolts in total so not designed to be easily dismantled for storage as far as I can see.