Cryoine

Active Member

I know I am committing a mortal sin by starting another project before my other project (Admirable Nelson) is completed

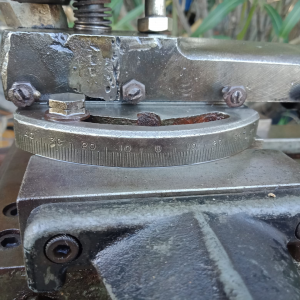

but I moved over one of the additional Lathes that I picked up from the machine shop, a 1966-69 a Myford ML7 Lathe(I've gotten so used to typing Utilathe). Additionally I also moved over one of the two Medding's drill press.

So far I just did the preliminary tear down and semi clean so ensure that things are in order.

you will notice a layer of structural dust/grime on the entire bed way that is what seems to have gotten the carriage stuck.

Ye Old Problems

Seized Spindle

Seized Tumbler gear(smaller one)

Seized Cross slide

Seized Carriage(there seems to be a theme here)

Seized Tailstock quill

Seized Compound slide

Top half of the lead screw has rust

Oilers are busted

motor state (I am unsure of as of now, but ill just add it here for good measure lol)

but I moved over one of the additional Lathes that I picked up from the machine shop, a 1966-69 a Myford ML7 Lathe(I've gotten so used to typing Utilathe). Additionally I also moved over one of the two Medding's drill press.

So far I just did the preliminary tear down and semi clean so ensure that things are in order.

you will notice a layer of structural dust/grime on the entire bed way that is what seems to have gotten the carriage stuck.

Ye Old Problems

Seized Spindle

Seized Tumbler gear(smaller one)

Seized Cross slide

Seized Carriage(there seems to be a theme here)

Seized Tailstock quill

Seized Compound slide

Top half of the lead screw has rust

Oilers are busted

motor state (I am unsure of as of now, but ill just add it here for good measure lol)

Attachments

-

WhatsApp Image 2023-04-14 at 4.19.48 PM (2).jpeg323.9 KB · Views: 28

WhatsApp Image 2023-04-14 at 4.19.48 PM (2).jpeg323.9 KB · Views: 28 -

WhatsApp Image 2023-04-20 at 2.14.54 PM.jpeg64.5 KB · Views: 27

WhatsApp Image 2023-04-20 at 2.14.54 PM.jpeg64.5 KB · Views: 27 -

WhatsApp Image 2023-04-20 at 2.14.53 PM.jpeg225.2 KB · Views: 22

WhatsApp Image 2023-04-20 at 2.14.53 PM.jpeg225.2 KB · Views: 22 -

WhatsApp Image 2023-04-20 at 2.14.53 PM (3).jpeg127.5 KB · Views: 19

WhatsApp Image 2023-04-20 at 2.14.53 PM (3).jpeg127.5 KB · Views: 19 -

WhatsApp Image 2023-04-20 at 2.14.53 PM (2).jpeg215 KB · Views: 20

WhatsApp Image 2023-04-20 at 2.14.53 PM (2).jpeg215 KB · Views: 20 -

WhatsApp Image 2023-04-20 at 2.14.53 PM (1).jpeg184.1 KB · Views: 21

WhatsApp Image 2023-04-20 at 2.14.53 PM (1).jpeg184.1 KB · Views: 21 -

WhatsApp Image 2023-04-14 at 4.19.49 PM (2).jpeg237.7 KB · Views: 21

WhatsApp Image 2023-04-14 at 4.19.49 PM (2).jpeg237.7 KB · Views: 21 -

WhatsApp Image 2023-04-14 at 4.19.49 PM (1).jpeg324.1 KB · Views: 22

WhatsApp Image 2023-04-14 at 4.19.49 PM (1).jpeg324.1 KB · Views: 22 -

WhatsApp Image 2023-04-14 at 4.19.48 PM.jpeg306.6 KB · Views: 23

WhatsApp Image 2023-04-14 at 4.19.48 PM.jpeg306.6 KB · Views: 23 -

WhatsApp Image 2023-04-14 at 4.19.48 PM (1).jpeg355.1 KB · Views: 26

WhatsApp Image 2023-04-14 at 4.19.48 PM (1).jpeg355.1 KB · Views: 26