Canadium

Ian

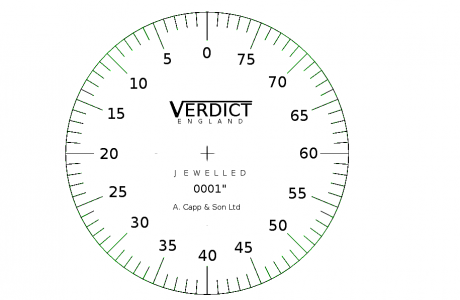

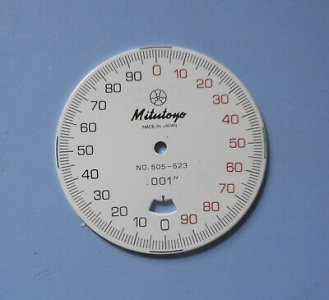

I got this used Mitutoyo dial caliper (model 505-626) at the recent auction. When I got it home I discovered it was so jammed with gunk it didn't work. So a disassembly and thorough cleaning was in order. It took me awhile to figure out how exactly the dial is designed in the Mitutoyo calipers. It seems every brands design differs around the dial assembly. After extensive searching around the net I finally found the clues needed to disassemble it enough for a complete cleaning. The pile of small parts looked daunting but after cleaning everything I got it mostly reassembled. There are however a couple of serious glitches. For one the movement is just a little stiff and no amount of adjustment seems to eliminate this. More serious however is that the dial was damaged before. Someone had obviously tried this before and in the process damaged the outside edge of the dial so that the paint along with the graduation marks is now flaking off around the edges. Looks like either I have to make myself a new dial or trash the calipers. Cutting a new aluminum disk and painting on the white background would be pretty easy. The trick would be getting the fine graduation marks on it. Any thoughts any one?