historicalarms

Ultra Member

From another forum I visit daily....The man is a true "artisan" in the truest form of both manual & CNC machining. Some of his other projects that have been covered include Falling Block rifle actions from a billet ( I would put them in the same "wow" class as the fishing reels we have seen on here). His present project is a double headed home built deep hole boring & rifling machine.

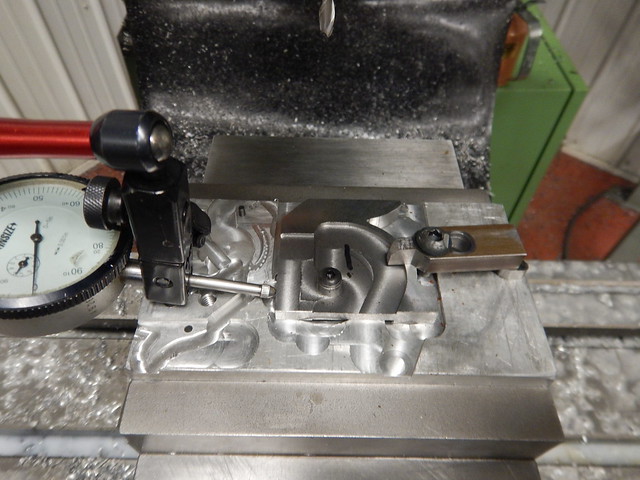

Another, related project I've recently completed is to build a "steady" that will allow me to support long skinny work pieces such as this 1" NC thread I turned down and cut @ 24" long.

(should be very handy for contouring barrels)

Basically, Its a heavy wall tube(loaded with sand) that mounts to the machine ways behind the chuck and between the carriage and tailstock.

It has two "vices" each with independent jaws. The jaws have replaceable "pads" that support the work piece and the cutting tool can cut right on by.

As the tool passes by the first vice, thereby reducing the part diameter, the jaws are adjusted to compensate. By having two vices next to each other, the work piece is never unsupported.

Seems to work pretty slick!

Another, related project I've recently completed is to build a "steady" that will allow me to support long skinny work pieces such as this 1" NC thread I turned down and cut @ 24" long.

(should be very handy for contouring barrels)

Basically, Its a heavy wall tube(loaded with sand) that mounts to the machine ways behind the chuck and between the carriage and tailstock.

It has two "vices" each with independent jaws. The jaws have replaceable "pads" that support the work piece and the cutting tool can cut right on by.

As the tool passes by the first vice, thereby reducing the part diameter, the jaws are adjusted to compensate. By having two vices next to each other, the work piece is never unsupported.

Seems to work pretty slick!