Hello,

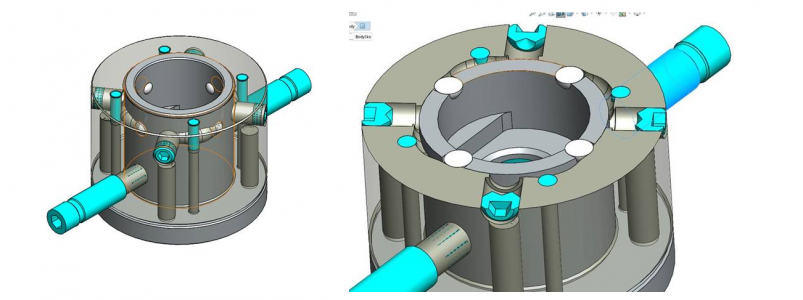

I was wondering if anyone had any solutions for a coating application I am looking for. What I am designing is a quick change system to be used in thermoforming tools. It consists of an internal retainer that will house the balls and accept a stud as well as an external ring that rotates allowing the balls to be released or locked. This will remain fixed in position and the rotation will only take place when they are changing out tooling so it will not be a constant motion.

My initial thoughts for materials are a 7075 aluminum external ring and a steel internal retainer. I am not locked into those materials though. I could go both aluminum or both steel if there are coatings that will meet the needs.

I would need coatings that will provide corrosion resistance, reduced friction in a dry run application and resistance to wear from the stainless steel balls when rotating. The thickness of the coating would need to be very thin like nickel plating or at least have a tight tolerance if I need to accommodate for a thicker coating in the machining of the components. I would also need a coating that doesn’t flake off easily with these actions since the component that mounts to this will make contact with the film during the forming operation.

Any assistance you can give me would be greatly appreciated.

I was wondering if anyone had any solutions for a coating application I am looking for. What I am designing is a quick change system to be used in thermoforming tools. It consists of an internal retainer that will house the balls and accept a stud as well as an external ring that rotates allowing the balls to be released or locked. This will remain fixed in position and the rotation will only take place when they are changing out tooling so it will not be a constant motion.

My initial thoughts for materials are a 7075 aluminum external ring and a steel internal retainer. I am not locked into those materials though. I could go both aluminum or both steel if there are coatings that will meet the needs.

I would need coatings that will provide corrosion resistance, reduced friction in a dry run application and resistance to wear from the stainless steel balls when rotating. The thickness of the coating would need to be very thin like nickel plating or at least have a tight tolerance if I need to accommodate for a thicker coating in the machining of the components. I would also need a coating that doesn’t flake off easily with these actions since the component that mounts to this will make contact with the film during the forming operation.

Any assistance you can give me would be greatly appreciated.