Redneck_Sophistication

Super User

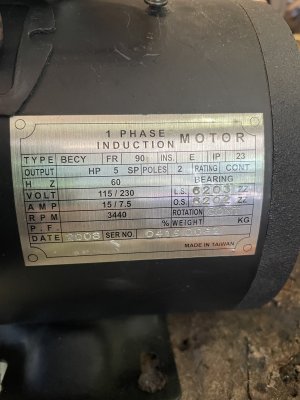

Well I thought I scored when I found a 5hp motor in like new shape at the local surplus store at a reasonable price. I didn’t notice it was labeled in the opposite rotation.

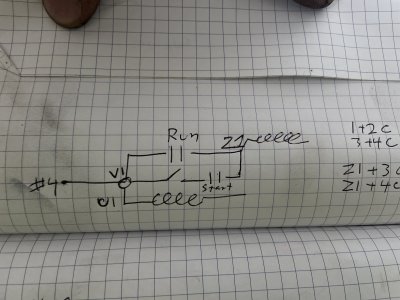

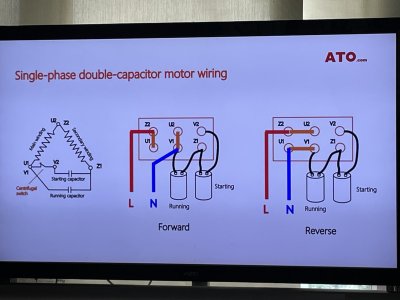

I know you can rewire by reverse the starter winding, but I can’t find a diagram that matches my 110/220v start and run cap motor. And it is not wired in the six wire configuration but 4 wire and the only label is for 110/220 connection. And both pairs of windings are the same size.

#1,2,3 all run directly into the windings

#4 is at U1/V1 I’m guessing. Attaches to windings and run cap, and to the start switch clutch/cap both caps connect to the same winding (Z1?)

wires 1&2 and 3&4 show connection on my ohmmeter

As well as Z1 to 3, and 4.

Tested with the caps disconnected.

having 5 connection points to the windings is messing me up. Can’t wrap my head around it today. Maybe some one can keep

Me from hurling this thing across the shop. Just want to get this lathe turning!!

Much appreciated brothers

I know you can rewire by reverse the starter winding, but I can’t find a diagram that matches my 110/220v start and run cap motor. And it is not wired in the six wire configuration but 4 wire and the only label is for 110/220 connection. And both pairs of windings are the same size.

#1,2,3 all run directly into the windings

#4 is at U1/V1 I’m guessing. Attaches to windings and run cap, and to the start switch clutch/cap both caps connect to the same winding (Z1?)

wires 1&2 and 3&4 show connection on my ohmmeter

As well as Z1 to 3, and 4.

Tested with the caps disconnected.

having 5 connection points to the windings is messing me up. Can’t wrap my head around it today. Maybe some one can keep

Me from hurling this thing across the shop. Just want to get this lathe turning!!

Much appreciated brothers