-

Spring 2024 meetup in Calgary - date Saturday, April 20/2024. discussion Please RSVP Here to confirm and get your invitation and the location details. RSVP NOW so organizers can plan to get sufficient food etc. One week to go! More info and agenda

-

We are having email/registration problems again. Diagnosis is underway. New users sorry if you are having trouble getting registered. We are exploring different options to get registered. Contact the forum via another member or on facebook if you're stuck. Update -> we think it is fixed. Let us know if not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for a Lathe Face Plate and a Lathe Dog Drive Plate

- Thread starter YYCHM

- Start date

TOBARApprentice

Super User

Hey Craig..... pretty sure I have both. Just finishing dinner and I’ll have a look. Give me 20 min.

Derek

Sent from my iPhone using Tapatalk

Derek

Sent from my iPhone using Tapatalk

TOBARApprentice

Super User

Sorry Craig..... I was positive I had both but I did a big clean out and they must have gone out in one of the boxes.... good luck.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sorry Craig..... I was positive I had both but I did a big clean out and they must have gone out in one of the boxes.... good luck.

TOBARApprentice

Super User

They did...... just threw out a bunch of stuff that had been kicking around. I know, “shop blasphemy”. Sometimes a good clean out is necessary. Good luck in the hunt.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

TOBARApprentice

Super User

I know that you are joking about the taking that “hunk” of metal to the dump..... because it weighs too much for one guy to lift, lol! There was a single box that was to go to my mother in laws garage to be stored, and it was “inadvertently” offloaded at the transfer station. I lost a few “goodies”, yes..... but I’ll find more!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

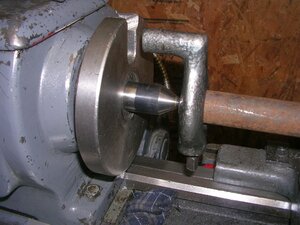

Ooooops... this isn't going to work very well...

So I guess I'm gonna need a dog with a longer leg or a MT3 dead center with a shorter nose?

My lathe is equipped with a taper attachment so I should be able to make an MT3 taper no problem. The question is once the taper is turned how would one secure the work piece to turn the 60 deg dead center point?

BTB - Still looking for a face plate.....

So I guess I'm gonna need a dog with a longer leg or a MT3 dead center with a shorter nose?

My lathe is equipped with a taper attachment so I should be able to make an MT3 taper no problem. The question is once the taper is turned how would one secure the work piece to turn the 60 deg dead center point?

BTB - Still looking for a face plate.....

I believe the expression is "That dog is not going to hunt!"Ooooops... this isn't going to work very well...

View attachment 11446

So I guess I'm gonna need a dog with a longer leg or a MT3 dead center with a shorter nose?

My lathe is equipped with a taper attachment so I should be able to make an MT3 taper no problem. The question is once the taper is turned how would one secure the work piece to turn the 60 deg dead center point?

BTB - Still looking for a face plate.....

What about a small piece mild steel in the 3J with a center point turned in situ? The dog will probably be long enough to engage on one of the jaws.

Another option is to use a bolt (say 1/2”) held on the dog with gear clamps to extend the “tail” into the drive plate slot.

Another option is to use a bolt (say 1/2”) held on the dog with gear clamps to extend the “tail” into the drive plate slot.

What about a small piece mild steel in the 3J with a center point turned in situ? The dog will probably be long enough to engage on one of the jaws.

That's what I have been doing to this point in time. The point of this exercise is to deploy the MT3 taper in the headstock and acquired another piece of what would have been original equipment for the lathe.

I'm really surprised my MT3 dead center sticks out as far as it does. I should be able to make a dead center that would work, it's the chicken before the egg dilemma that's got me stumped.

Dabbler

ersatz engineer

+1 to Robin hood's way. it really is the most accurate way to do what you want. Using a dead centre in the taper is a far less acccurate way to turn from centres....

You can use the MT3 in the heaststock for line boring, but that's about all it is useful for. I've even used it for doing boring using a boring head, but never turning between centres.

You can use the MT3 in the heaststock for line boring, but that's about all it is useful for. I've even used it for doing boring using a boring head, but never turning between centres.

Johnwa

Ultra Member

My Southbend has the same issue. IIRC the spindle taper is similar to a MT3 but is not bored as deep. Without researching, I believe an MT2 with an adaptor was supposed to be used. Some of the older books say that a soft center was used and would be trued up like @RobinHood described.

I find between center turning is quite useful when a piece has to be removed often to check fits or if it gets swapped end for end.

I find between center turning is quite useful when a piece has to be removed often to check fits or if it gets swapped end for end.

I just checked the parts list in the manual and Johnwa is correct, MT2 and a sleeve.I believe an MT2 with an adaptor was supposed to be used.

Tom Kitta

Ultra Member

Ooooops... this isn't going to work very well...

View attachment 11446

So I guess I'm gonna need a dog with a longer leg or a MT3 dead center with a shorter nose?

My lathe is equipped with a taper attachment so I should be able to make an MT3 taper no problem. The question is once the taper is turned how would one secure the work piece to turn the 60 deg dead center point?

BTB - Still looking for a face plate.....

Drill and tap a hole in your plate and put a bar in it. Problem solved.

I haven't done a lot of dog turning but I actually find most of them to be kind of hit & miss. Either the return arm is too short as you are experiencing. Or it covers up so much of the shaft. The retention basically boils down to cinching that bolt in the vee notch so unless you are also going to mill a flat on the part, I don't get why the whole arm has to be so massive. Also dog plates are getting harder to find.

I've drawn up a CAD design for a dog that is made from simple plate say 1/2" thick. Progressively larger series of plates so like 0-.5" stock, 0.5-1.0" etc. Then its arm holds a pin of any length that can rest in the dog plate or chuck jaw or faceplate. I'm told faceplates aren't really meant for transmitting torque like this though. I'll dig up the design if you are interested. The trick is making the teardrop internal shape. I also had a thought to make a dog plate from a ordinary chuck adapter plate, D1-4 in my case.

Anyways one thing to remember, if you are threading using the dog, always ensure pre-contact with the pin & chuck before in-feeding so threads don't get out of phase.

I've drawn up a CAD design for a dog that is made from simple plate say 1/2" thick. Progressively larger series of plates so like 0-.5" stock, 0.5-1.0" etc. Then its arm holds a pin of any length that can rest in the dog plate or chuck jaw or faceplate. I'm told faceplates aren't really meant for transmitting torque like this though. I'll dig up the design if you are interested. The trick is making the teardrop internal shape. I also had a thought to make a dog plate from a ordinary chuck adapter plate, D1-4 in my case.

Anyways one thing to remember, if you are threading using the dog, always ensure pre-contact with the pin & chuck before in-feeding so threads don't get out of phase.

Brent H

Ultra Member

Just home @YYCHobbyMachinist, I brought home some 9” x 7/8” round stock - yes 9”!! Plan is to make a face plate/ dog drive for my lathe - I will post the results/progress as it goes. Lots of projects will be on the go but this one might be of interest to you.

Don't know how I'm gonna put a point on her???

Stick it into the spindle, set your compound to 30* off the longitudinal axis, and turn the point. Will give you a 60* included center. Mark the position of the MT3 slug so that you can repeat the orientation next time you put the center into the spindle. For better accuracy, take a skim cut on the point each time you re-insert the center into the spindle.