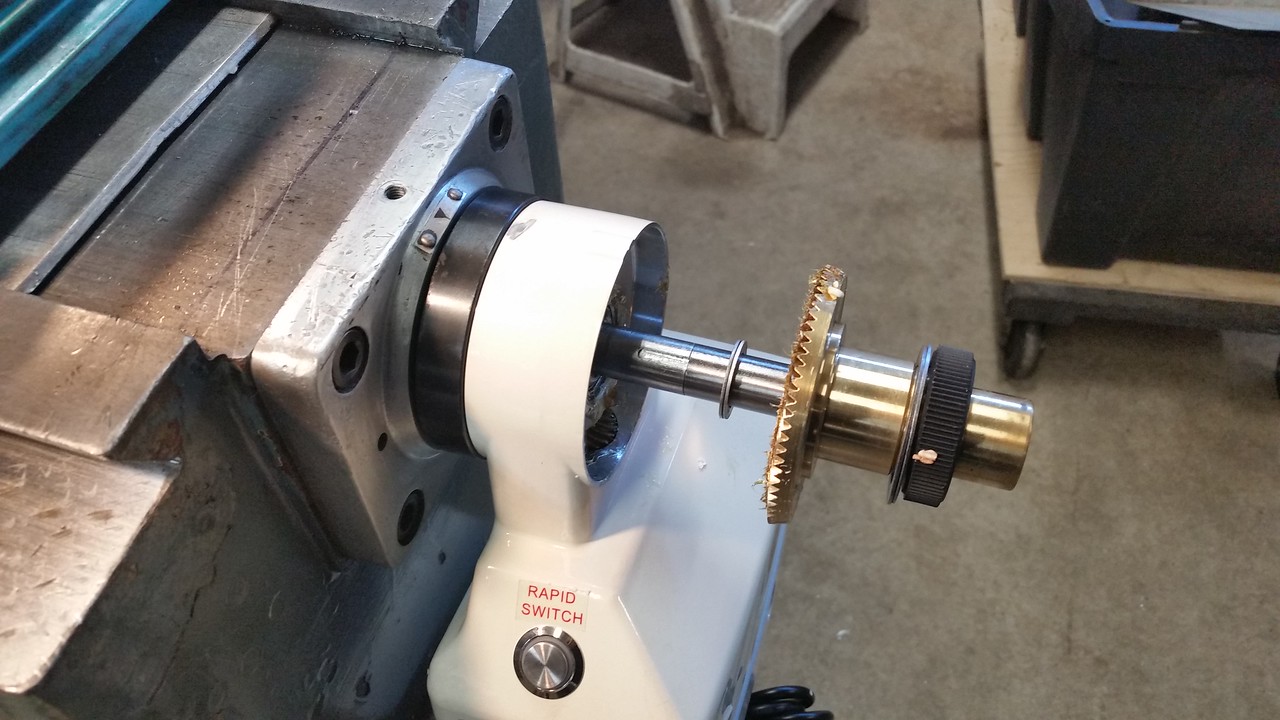

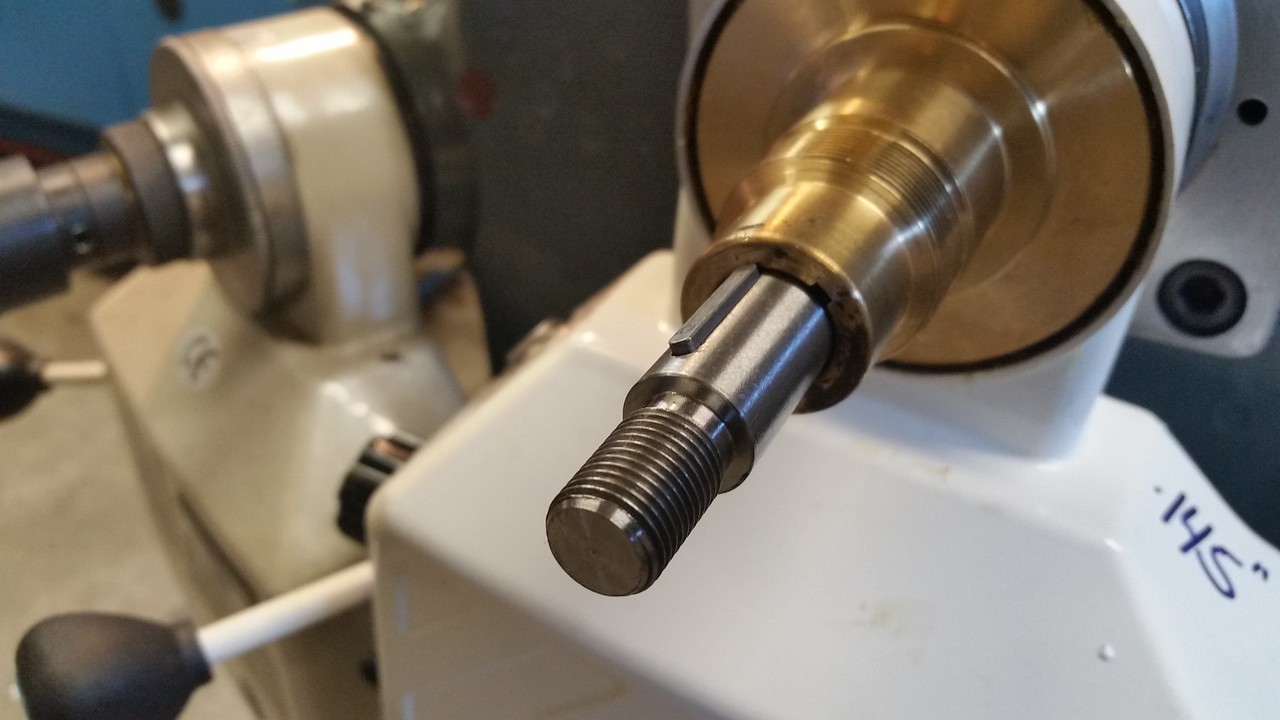

I paid $160 tax in from Vevor Canada.

https://vevor.ca/products/power-fee...ling-machine-110v?_pos=1&_sid=4b4240a60&_ss=r

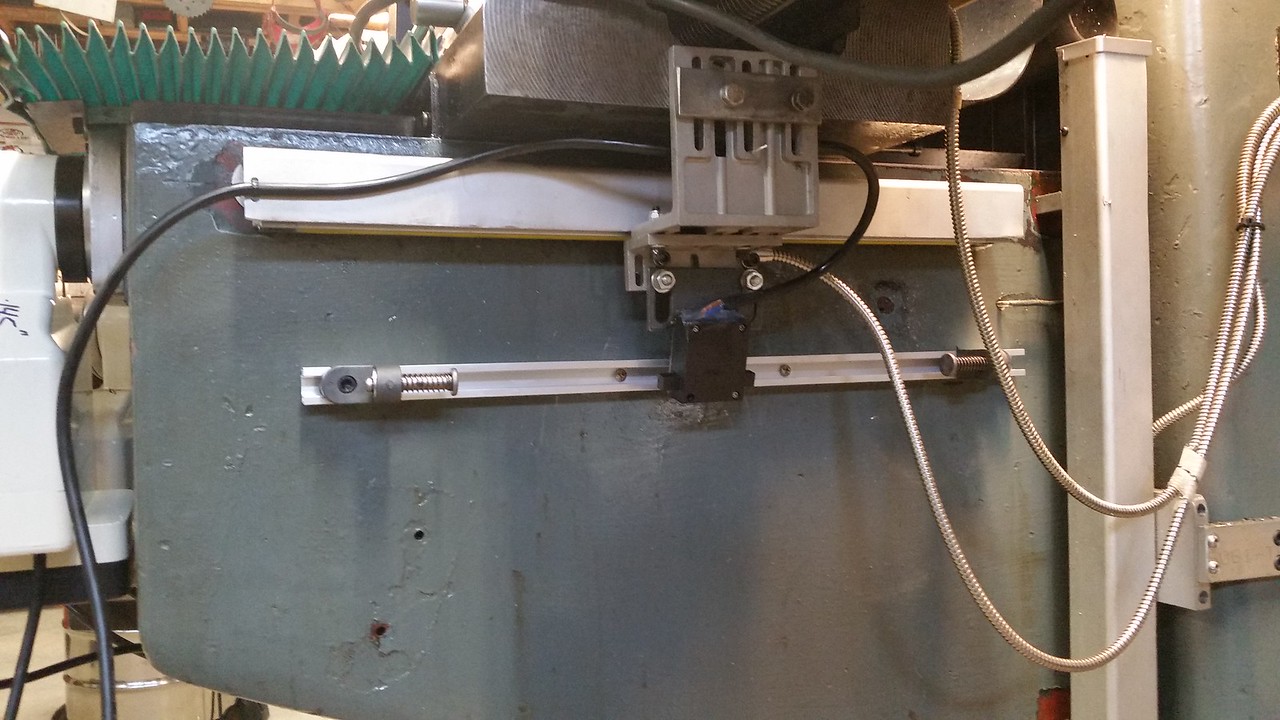

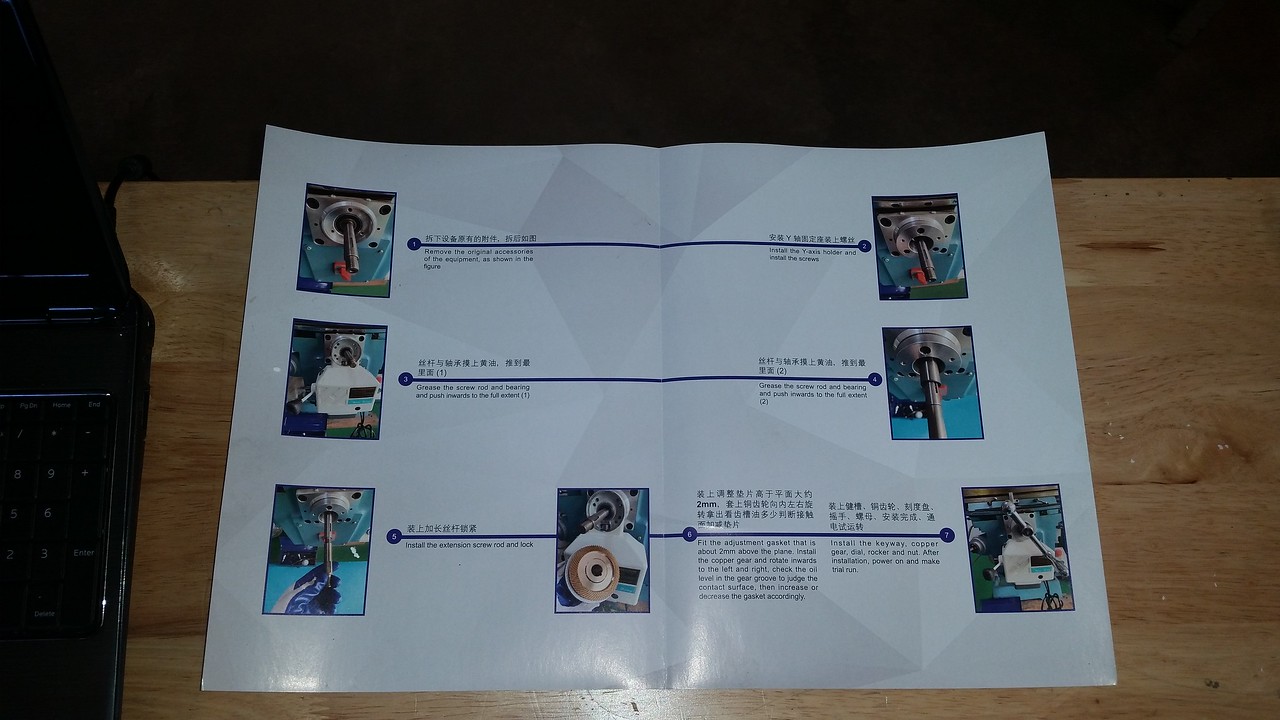

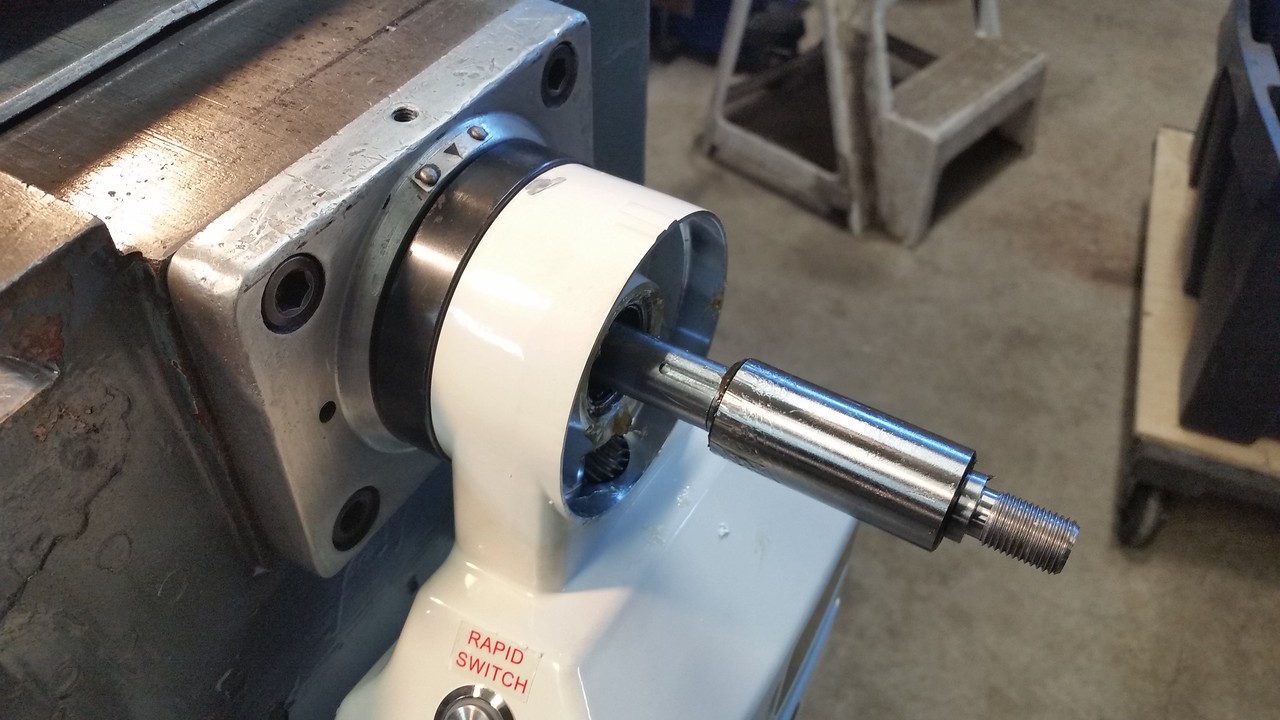

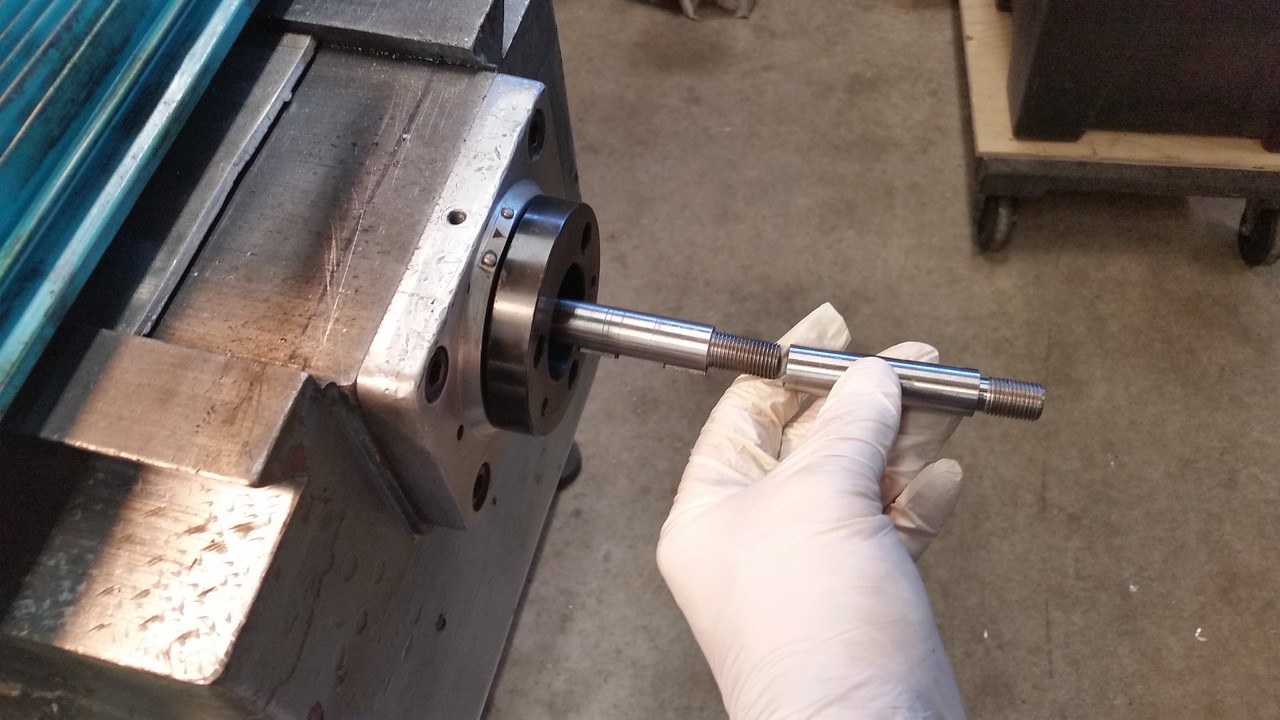

The kit was very complete and installed with no issues. It seems to work fine so far. Less than half the price I paid for the Z axis one I bought last year.

https://vevor.ca/products/power-fee...ling-machine-110v?_pos=1&_sid=4b4240a60&_ss=r

The kit was very complete and installed with no issues. It seems to work fine so far. Less than half the price I paid for the Z axis one I bought last year.