Hi All,

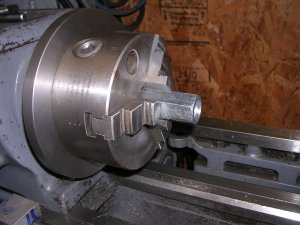

This is my first post, and I hope it is appropriate. I am very new to metal machining, and for the first time I venture out of drill press and hand file type of things. So, I bought an old mini lathe. It is missing any auto feed, but it has a chuck (for which I cannot get any keys, they seem to be 7.5 mm hex) and a 1/4" tool post.

Could you please help identifying it? My hope is to find manuals and parts for the thing. Thanks !

This is my first post, and I hope it is appropriate. I am very new to metal machining, and for the first time I venture out of drill press and hand file type of things. So, I bought an old mini lathe. It is missing any auto feed, but it has a chuck (for which I cannot get any keys, they seem to be 7.5 mm hex) and a 1/4" tool post.

Could you please help identifying it? My hope is to find manuals and parts for the thing. Thanks !