-

Spring 2024 meetup in Calgary - date Saturday, April 20/2024. discussion Please RSVP Here to confirm and get your invitation and the location details. RSVP NOW so organizers can plan to get sufficient food etc. One week to go! More info and agenda

-

We are having email/registration problems again. Diagnosis is underway. New users sorry if you are having trouble getting registered. We are exploring different options to get registered. Contact the forum via another member or on facebook if you're stuck. Update -> we think it is fixed. Let us know if not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good source for link belts?

- Thread starter slow-poke

- Start date

Proxule

Ultra Member

Be aware they are directional, They will run in both directions but could cause snagging or vibration in reverse.I have yet to try the fancy link belts, seems like people using them feel they are better than the old V-belts.

I do notice my V-belts do take a shape.

can anyone recommend a good Canadian source?

I also found they did not perform as well at transmitting power, tested ( machinery in the field ) and not on a lathe or mill.

They did tend to run quieter then regular nylon/rubber carcass.

leevalley has some or perhaps amazon.

Gluck

slow-poke

Ultra Member

Can you please expand on your comment "not on a mill"Be aware they are directional, They will run in both directions but could cause snagging or vibration in reverse.

I also found they did not perform as well at transmitting power, tested ( machinery in the field ) and not on a lathe or mill.

They did tend to run quieter then regular nylon/rubber carcass.

leevalley has some or perhaps amazon.

Gluck

I was thinking for my drill press and possibly mill.

Proxule

Ultra Member

You are correct. Sorry the wording was improper.I think he meant had not power tested on a mill or lathe.

I get link belts at Lee Valley. Not cheap but very effective.

My exp has been on machinery in the field. Not on machinery in the shop. Like a mill or lathe.

They run a lot smoother than regular V-belts. I have three regular belts, two are new, but they all run thumpy on my lathe where as the link belt is very smooth. They will stretch a bit as they settle so you will need to adjust the length after a bit of running.

LV only shows the one size but KMS has three sizes.

LV only shows the one size but KMS has three sizes.

I didn't realize they were directional but I guess given how they are made that makes sense.

Six O Two

(Marco)

amazon...

the 5' length was somewhat frustrating to me. Just a bit short for two belts, not sure what I'll use my remnant for...

the 5' length was somewhat frustrating to me. Just a bit short for two belts, not sure what I'll use my remnant for...

I had them on my old mill/lathe combination and liked them. Apparently because of the link structure the 60 cycle vibration that a motor can generate is no transmitted through the belt like a solid belt will do. I bought mine from Busy Bee. They were Power Twist.

The five ft lengths on Amazon are a good price. I paid $51 for 3 ft yesterday at Lee Valley.What is a fair price for enough to do one belt?

I didn't know that either. That is a pretty serious disadvantage of them on alot of machinery.I didn't realize they were directional but I guess given how they are made that makes sense.

Former Member

Guest

I personally like them, they dampen vibration and find they have less slip. I know that by absorbing vibration there is a little power loss but I'll accept that for less vibration.

I am into the AMMEGA Megadyne facility every other week.

They supply custom & standard V, cog and flat belts for a wide variety of applications.

If you send me the specifications, I can pass it onto their Design Engineers.

It may take a few weeks, but I will stay after them.

They supply custom & standard V, cog and flat belts for a wide variety of applications.

If you send me the specifications, I can pass it onto their Design Engineers.

It may take a few weeks, but I will stay after them.

I do however have the perfect application for one link belt...on a 50+ year old table saw that probably has the original belt on it and it gets turned on only a few times a year. The belt always runs rough and thumps until it looses the shape from sitting for so long. Too bad I was so cheap.I didn't know that either. That is a pretty serious disadvantage of them on alot of machinery.

I've resisted putting link belts on my Unisaw because to do so would cost more than I paid for the saw.I do however have the perfect application for one link belt...on a 50+ year old table saw that probably has the original belt on it and it gets turned on only a few times a year. The belt always runs rough and thumps until it looses the shape from sitting for so long. Too bad I was so cheap.

I did have a look at MEGADYNE’s website . . .

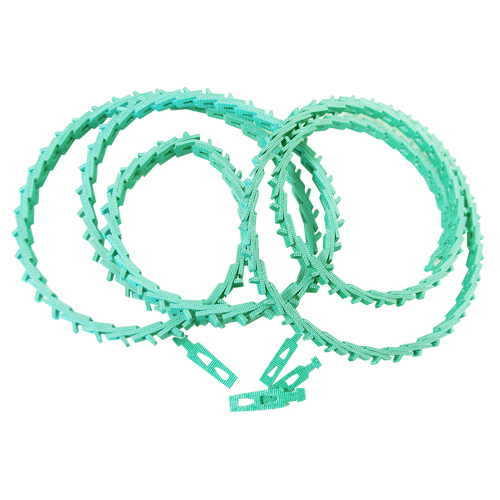

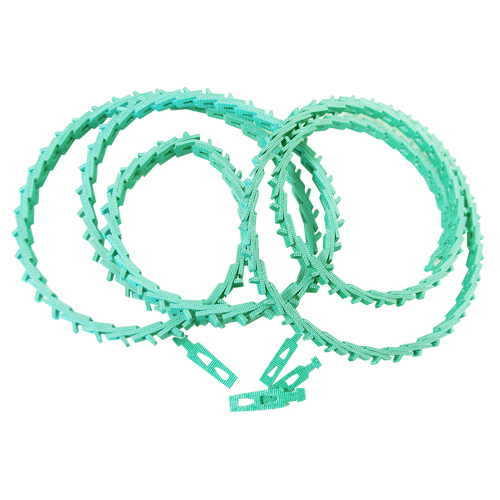

They have a whole catalogue of Accu-Link® belts.

megadynegroup.com

megadynegroup.com

They have a whole catalogue of Accu-Link® belts.

Accu-Link®

Constructed with wear and oil resistant urethane and reinforced with high strength polyester, todays Accu-Link® is designed to save labor and costs by offeri

I used link belts on Herbert 2d lathes for many months with instant reverse applied for threading and tapping operations. These were lower rpm operations.I didn't know that either. That is a pretty serious disadvantage of them on alot of machinery.

I also use link belts on one of my drill presses with great success.

I use them on my 14x60 lathe, belt sander and horizontal bandsaw. The bandsaw is in an unheated garage. The standard V belt would thump and bounce. The link belt is smooth regardless of temperature. I have run them both ways without problem. I did not know they were directional at first.