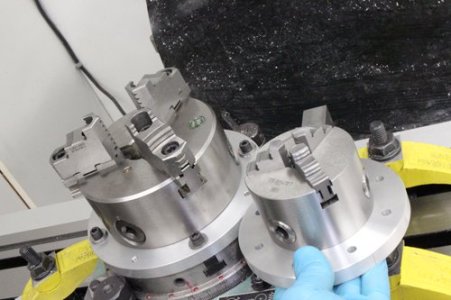

A while back I bought a Harlingen 3" chuck & was impressed with the quality. This was after buying a very similar looking POS which was a real let down. Both chucks made in Asia but the Harlingen is heads & tails better. Anyway I added to the collection. I have a 3J, 4J independent & 4J scroll. You can get an integral 5C adapter back plate which makes a happy marriage to a spin indexer. I tend to use these chucks a lot because many of my parts are small I finicky. I made a rectangular tooling plate which bolts to the chuck & then I can hold that in my vise, or at angles... very convenient for holding round things by OD or ID but leaving the main mill vise in position. Thankfully they are all on the same bolt pattern so can be swapped on plates.

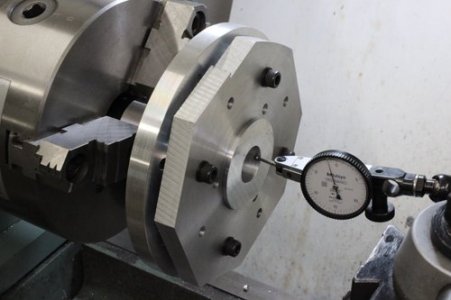

I typically have a 5" Gator chuck mounted to my RT but I decided I wanted a plate for 3" for smaller stuff yet, because why not. So that's what you see here. I used up some leftover scraps of cast aluminum jig plates which is is finish ground on both sides. It also used my new mini faceplate. I cant think making these fixture plates out of steel would be a lot of fun with all the bandsaw lopping off & interrupted cutting.

I typically have a 5" Gator chuck mounted to my RT but I decided I wanted a plate for 3" for smaller stuff yet, because why not. So that's what you see here. I used up some leftover scraps of cast aluminum jig plates which is is finish ground on both sides. It also used my new mini faceplate. I cant think making these fixture plates out of steel would be a lot of fun with all the bandsaw lopping off & interrupted cutting.