I just picked this up from Facebook Marketplace. It's missing a few pieces, but the motor sounded good, no noise from the bearings, and no play or looseness. It is designed for lathes between 8"-14", and my lathe has a 16" swing, but I'm sure I can make a new mounting post to make it work.

-

Spring 2024 meetup in Calgary - date Saturday, April 20/2024. discussion Please RSVP Here to confirm and get your invitation and the location details. RSVP NOW so organizers can plan to get sufficient food etc. It's Tomorrow Saturday! you can still RSVP until I stop checking my phone tomorrow More info and agenda

-

We are having email/registration problems again. Diagnosis is underway. New users sorry if you are having trouble getting registered. We are exploring different options to get registered. Contact the forum via another member or on facebook if you're stuck. Update -> we think it is fixed. Let us know if not.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Dumore #44

- Thread starter thestelster

- Start date

Tool

Well, I just quickly went over the unit. I should have titled this post Caveat Emptor!!

I'm a little disappointed. The bearings and motor feel and sound good, but the unit comes with 5 pulleys for speed changes. Two of them have been modified, and made useless. The chuck assembly for mounted stones, and small wheel arbor, have been modified and made useless. The belt guard assembly is missing. The wheel guard seems to have been modified and the wheel guard face plate is missing. I was so excited at finding this I didn't do my due diligence research. So checking the Dumore site, to replace all those parts will run me $677.00US, not including shipping, and taxes. Oh well, it is what it is.

I'm a little disappointed. The bearings and motor feel and sound good, but the unit comes with 5 pulleys for speed changes. Two of them have been modified, and made useless. The chuck assembly for mounted stones, and small wheel arbor, have been modified and made useless. The belt guard assembly is missing. The wheel guard seems to have been modified and the wheel guard face plate is missing. I was so excited at finding this I didn't do my due diligence research. So checking the Dumore site, to replace all those parts will run me $677.00US, not including shipping, and taxes. Oh well, it is what it is.

Attachments

Well, if the motor is good, the rest can prolly be saved. If anyone can do it you can.

You can make your own pulleys.

You can make or adapt your own chuck - prolly way better than the original.

You can also make your own gaurds and face plates better than the originals.

I would stay excited if I were you. Just think about it as what it will be when you are all done with it rather than what it was when you got it off marketplace.

I'm still jealous!

You can make your own pulleys.

You can make or adapt your own chuck - prolly way better than the original.

You can also make your own gaurds and face plates better than the originals.

I would stay excited if I were you. Just think about it as what it will be when you are all done with it rather than what it was when you got it off marketplace.

I'm still jealous!

I hear the big money is in the spindle bearings so hopefully they are in good shape. Never been inside one so cant offer any words of wisdom.

Did many stones come with?

Just curious does motor run in both directions or just one way? It never dawned on me before that this (one way) may well be a function of spindle mandrel not unscrewing itself.

Did many stones come with?

Just curious does motor run in both directions or just one way? It never dawned on me before that this (one way) may well be a function of spindle mandrel not unscrewing itself.

I have a complete #44.

There was no belt guard on the old machines. At least on mine there is no provision for one on the belt side.

Your wheel guard looks complete. There is no face covering. It is held to the spindle body with a single machine screw (which you have). Wheel guard is only used for OD grinding.

Yes, the motor runs in only one direction. It has LH thread on the shaft. Both sides of the spindle have RH threads so that either the pulley or the grinding stones/mounted stones have a tendency to tighten their respective threads during grinding.

I believe there are only 5 pulleys. You need the 2” and 3” one remade (or purchase them, as they are precision balanced).

If you need a flat belt, Transmission Supply can get them for you - that’s where I got my replacements.

Let me know if you need close-up pictures of parts or specific dimensions.

Once you get it running, let me know what grinding wheels you need. I have lots of NOS original Dumore stones.

There was no belt guard on the old machines. At least on mine there is no provision for one on the belt side.

Your wheel guard looks complete. There is no face covering. It is held to the spindle body with a single machine screw (which you have). Wheel guard is only used for OD grinding.

Yes, the motor runs in only one direction. It has LH thread on the shaft. Both sides of the spindle have RH threads so that either the pulley or the grinding stones/mounted stones have a tendency to tighten their respective threads during grinding.

I believe there are only 5 pulleys. You need the 2” and 3” one remade (or purchase them, as they are precision balanced).

If you need a flat belt, Transmission Supply can get them for you - that’s where I got my replacements.

Let me know if you need close-up pictures of parts or specific dimensions.

Once you get it running, let me know what grinding wheels you need. I have lots of NOS original Dumore stones.

I have a complete #44.

There was no belt guard on the old machines. At least on mine there is no provision for one on the belt side.

Your wheel guard looks complete. There is no face covering. It is held to the spindle body with a single machine screw (which you have). Wheel guard is only used for OD grinding.

Yes, the motor runs in only one direction. It has LH thread on the shaft. Both sides of the spindle have RH threads so that either the pulley or the grinding stones/mounted stones have a tendency to tighten their respective threads during grinding.

I believe there are only 5 pulleys. You need the 2” and 3” one remade (or purchase them, as they are precision balanced).

If you need a flat belt, Transmission Supply can get them for you - that’s where I got my replacements.

Let me know if you need close-up pictures of parts or specific dimensions.

Once you get it running, let me know what grinding wheels you need. I have lots of NOS original Dumore stones.

Hi RobinHood,

I downloaded the Operating manual and parts list from the Dumore website:

https://www.dumoretools.com/documents/Tool-Post-Grinders-Dumore-Series-44-Operating-Instructions.pdf

and it does show belt guards, and wheel guard front plate.

I will be purchasing the pulleys from them. They are crowned wheels and balanced, and I think it might be difficult to get the crown radius correct without tools that I don't have. I would think that if the crown wasn't correct the belt would slip off, or at least be off to one side. Besides, Dumore sells them for about $20.00 each, and I only need to replace the #2, and #3 pulleys, the others are good. What really sent me for a loop was that the Chuck assembly for mounted points, and the wheel arbor for small wheels get screwed into the shaft of the main spindle, but somebody drilled out the threads of those units. The wheel arbor is easy enough to make, but those chuck assemblies would be more difficult, they run about $75.00 each. The belt is $20.36, which seems fairly steep for what it is, so I will check with McMaster-Carr or a transmission supply like you suggested.

Thank you for your help and regarding the stones. I'm not sure what I need at the moment.

It's still better than the Dumore I don't have!

I believe I have that same Du More kit. If I remember right I think mine is a one half horse I haven’t used it for a while it’s still out in the box sleeping. If I can help you with information just let me know thanks

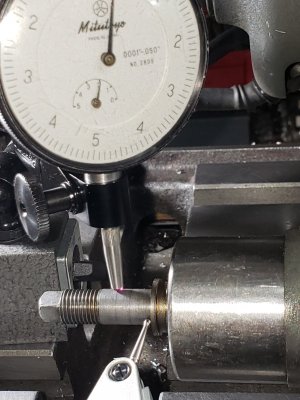

Well, I did some measurements at both ends of the spindle, and the faces. At the motor end, the spindle runout is almost zero, with a tenths indicator it just twitches. At its face, .0003" runout. At the wheel end, spindle runout is 0.0036", and at the face, 0.0011" runout. If you have a look at one of the pictures, you can see damage at the end of the threaded section, which incidentally corresponds with the low reading. Oh well, c'est la vie! I'll test the whole unit and see if it gives me acceptable results.

Attachments

That’s too bad about the runout. My guess is it had an unfortunate accident while in use or it was dropped with a stone/wheel mounted.

So went and checked my #44. There is in fact no provision for either a face cover on the wheel guard nor for a belt guard on the drive side.

I think @trlvn is correct that there must have been updates to the grinders over the years as OSHA rules were tightened.

So went and checked my #44. There is in fact no provision for either a face cover on the wheel guard nor for a belt guard on the drive side.

I think @trlvn is correct that there must have been updates to the grinders over the years as OSHA rules were tightened.

That’s too bad about the runout. My guess is it had an unfortunate accident while in use or it was dropped with a stone/wheel mounted.

So went and checked my #44. There is in fact no provision for either a face cover on the wheel guard nor for a belt guard on the drive side.

View attachment 22407

View attachment 22408

I think @trlvn is correct that there must have been updates to the grinders over the years as OSHA rules were tightened.

Hi RobinHood,

That looks exactly like mine. Thank you. I really appreciate you going through the effort.

So at least now I know I don't have to buy extra stuff, unless I decide to retro fit the belt guard (which is the least important part of this endeavor at the moment).

140mower

Don

I might be able to help with the spindle. I have one that I purchased with some collets if I remember correctly, thinking that for the price it would be a cheap spare for mine. When it arrived, I drug mine out only to discover that mine is a South Bend. Lol.

I put it in a drawer and have been doing my best to forget about it. I think there's three stone adapters..... I can try and get some pictures of what I have later. There's no pulleys though....

I think I am into them for around fifty and shipping.

I put it in a drawer and have been doing my best to forget about it. I think there's three stone adapters..... I can try and get some pictures of what I have later. There's no pulleys though....

I think I am into them for around fifty and shipping.

Hi Don, yes please. No rush. At your convenience. Thank you.I might be able to help with the spindle. I have one that I purchased with some collets if I remember correctly, thinking that for the price it would be a cheap spare for mine. When it arrived, I drug mine out only to discover that mine is a South Bend. Lol.

I put it in a drawer and have been doing my best to forget about it. I think there's three stone adapters..... I can try and get some pictures of what I have later. There's no pulleys though....

I think I am into them for around fifty and shipping.

140mower

Don

To be truthful, I know nothing about these things, but I think two are for internal grinding and one is external. Only the longest one has what appears to be enough pieces to mount a stone. The rest will need washers and mounting screws etc. I think the bearings feel smooth.......