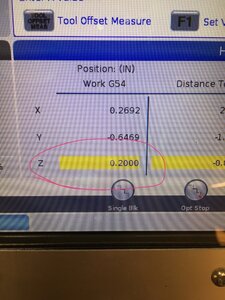

A frequent concern with CNC milling is making sure the top of the stock is known correctly and the tool in the spindle is set to the correct length. If either of these is wrong then you can ram the tool into the stock or table all too easily. I designed a height gauge to help confirm these details are correct. Below in the program line N55 moves the tool to 0.2" above the surface to be milled. Typically you step through the program to that line and then check the height. CAM programs typically generate this command before every new operation. Rulers are awkward to verify and just eyeballing it can be wrong. I don't know what other people do but I let the program slowly move the spindle to this height and then check it with the gauge. I started with a plastic one 3d printed which was very effective. Just recently I made one from aluminium. The step height on each step is actually a little under the nominal height so the gauge will just slide under the tool.

Figure 2 showing the CAM milling operations.

O00902 (Height Gauge side 2)

(Using G0 which travels along dogleg path.)

(T4 D=0.25 CR=0. TAPER=90deg - ZMIN=-0.007 - spot drill)

(T9 D=1.9587 CR=0.005 - ZMIN=-0.01 - face mill)

N10 G90 G94 G17

N15 G20

N20 G53 G0 Z0.

(Face1 2)

N25 T9 M6

N30 S1024 M3

N35 G54

N40 G0 X1.2731 Y0.0475

N45 G43 Z0.4 H9

N50 T4

N55 G0 Z0.2 <- STOP THE PROGRAM HERE AND CHECK HEIGHT

N60 G1 Z0.1859 F15.901

N65 G18 G3 X1.0773 Z-0.01 I-0.1959 K0.

N70 G1 X1.

N75 X-9. F24.182

Figure 2 showing the CAM milling operations.