GummyMonster

Ken

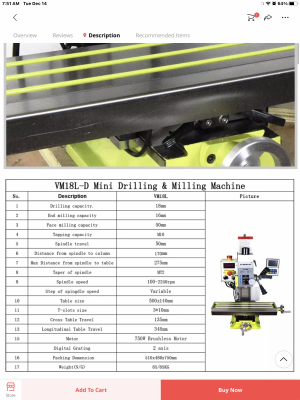

So over the summer I've been pondering the setup for my machines once I finally get it up and running, and I think CNC will be best. I have problems with my hands that cause trembling and jerky movements at times. I've been turning the hand wheels and I'm just not going to be smooth enough.

I've researched the conversations and I know how the system works, but to buy everything piece by piece will be hard as there's so many variables. Electronic systems are not something I've had much experience with.

I was browsing and found this - https://www.aliexpress.com/item/4000588951353.html

And it looks to me like exactly what I need.

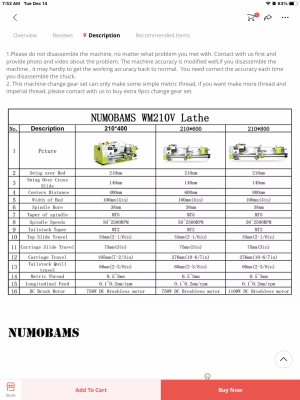

I'd have 3 axis control for the milling machine, and another motor for a power feed on my lathe.I guess I'm hoping a package like this would work for me.

Ken

I've researched the conversations and I know how the system works, but to buy everything piece by piece will be hard as there's so many variables. Electronic systems are not something I've had much experience with.

I was browsing and found this - https://www.aliexpress.com/item/4000588951353.html

And it looks to me like exactly what I need.

I'd have 3 axis control for the milling machine, and another motor for a power feed on my lathe.I guess I'm hoping a package like this would work for me.

Ken