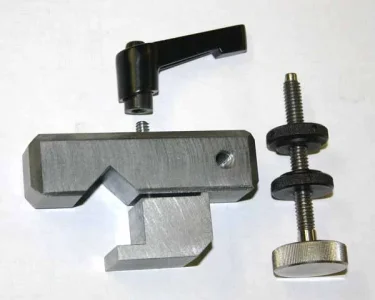

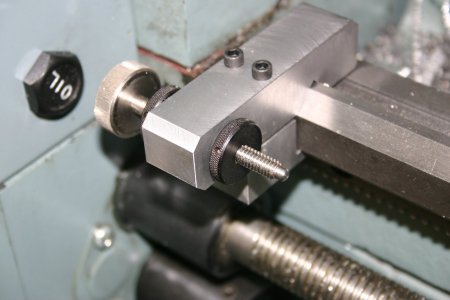

I did the same thing initially. On V2 I ditched the socket head cap screws in favor of a small handle. No more 'where is the hex wrench'. This style of handle has a spring inside so you can pull up, set it to an angle & it detents in that position. More liberal chamfers on all the edges. I prefer the big thumbscrew type of stop with locking nuts on either side, allows you to make minute stop adjustments but the clamp body stays in position. And if you ever make another, I recommend making 2. Nice to have one on the other side of saddle if you are traversing back & forth between 2 positions.