Matt-Aburg

Ultra Member

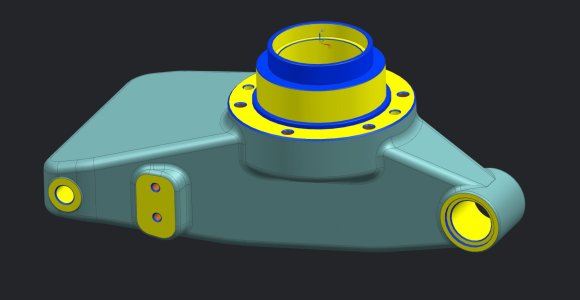

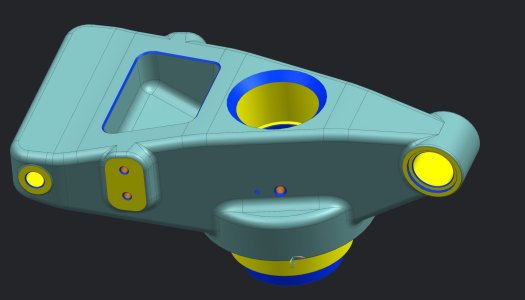

I have production work coming up. My prototype was made on a Bridgeport clone CNC conversion called Supra. This machine has its limitations as far as repeatability. I had to bore through 5.5 deep with a tolerance of plus 0.0000 / minus 0.0005. The bores front and back had to be aligned totally correct. This part is a bearing housing. The bearings on front and back MUST be aligned and press fit in with a minus 0.002 shrink fit. It was very nerve-racking working with a machine that would not return to exact position. another issue was trying to measure with the damn boring head in the way. I was scared to move the table for fear of being out of location due to the repeatability issues.

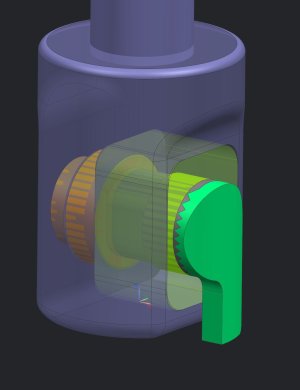

Moving forward, I would like to do this job again. This time using my CNC router. Now the problem will be high RPM's. A conventional boring head would not work as the balance would shake incredibly. I have found a solution to this problem with a product referenced on a video from a different thread. The guy running CNC toolmaking in his small garage. He uses products from the YouTube video below. I would imagine these cost a lot of moola. I will be making an inquiry though.

This is a boring head meant for high RPM's and is super rigid and accurate. They are BIG KAISER boring tools from BIG DAISHOWA.

www.bigdaishowa.com

www.bigdaishowa.com

Moving forward, I would like to do this job again. This time using my CNC router. Now the problem will be high RPM's. A conventional boring head would not work as the balance would shake incredibly. I have found a solution to this problem with a product referenced on a video from a different thread. The guy running CNC toolmaking in his small garage. He uses products from the YouTube video below. I would imagine these cost a lot of moola. I will be making an inquiry though.

This is a boring head meant for high RPM's and is super rigid and accurate. They are BIG KAISER boring tools from BIG DAISHOWA.

CNC Boring Tools

The precision of BIG KAISER modular CNC boring tools delivers measurable performance advantages—significantly reducing costs and cycle times.

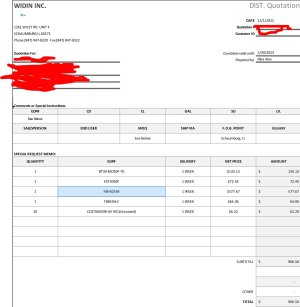

Attachments

Last edited: