Finished work and decided I needed an arbor for my newly delivered first slitting saw!

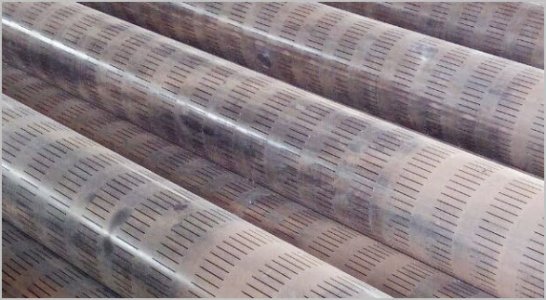

Shamelessly adapted from Blondihacks' video on the subject, I present you: Arbor the first.

A bit of turning work, threading work, drilling, tapping, and cutting off. Missed my dimension on the arbor shoulder by about 2 thou which was annoying. The remainder worked ok, though I have some minor order-of-operation concentricity concerns, mostly in drilling aftercutting off the screw section. That said, it cut on the first try!

On the downside, my setup for that slit was suspect, and I learned a lesson. At the cost of one tooth on the saw: If your work's not squared up, don't expect the vice to hold it stable. D'Oh.

I haven't put a DTI on the saw to measure its run-out. I do know the miss on the diameter of the seat makes the saw give a rhythmic chunk-chanck as it cuts - amazing how out by a couple of thou is so audible.

But I think it's good enough for its next use as I contemplate Harold Hall's simple dividing head and its split bearings.

Shamelessly adapted from Blondihacks' video on the subject, I present you: Arbor the first.

A bit of turning work, threading work, drilling, tapping, and cutting off. Missed my dimension on the arbor shoulder by about 2 thou which was annoying. The remainder worked ok, though I have some minor order-of-operation concentricity concerns, mostly in drilling aftercutting off the screw section. That said, it cut on the first try!

On the downside, my setup for that slit was suspect, and I learned a lesson. At the cost of one tooth on the saw: If your work's not squared up, don't expect the vice to hold it stable. D'Oh.

I haven't put a DTI on the saw to measure its run-out. I do know the miss on the diameter of the seat makes the saw give a rhythmic chunk-chanck as it cuts - amazing how out by a couple of thou is so audible.

But I think it's good enough for its next use as I contemplate Harold Hall's simple dividing head and its split bearings.

Last edited: